主要特色

廣泛的輸入/輸出規格

- 10 channel通用輸入模組可測量直流電壓,熱電偶,RTD和接觸輸入訊號。 提供16 channel數字輸入模組和繼電器輸出模組。

- GX90XA類比輸入模組:直流電壓,直流電流,熱電偶,RTD,接點

- New! GX90XA-10-V1:高耐壓AI模組:最大。 共模電壓600V

- GX90XA-04-H0高速AI模組:直流電壓,直流電流,熱電偶,RTD,接點

- GX90XA-06-R1 4線RTD模組:4線RTD,4線電阻

- GX90YA類比輸出模組:電流輸出(點數間隔離)

- GX90XD數位輸入模組:遙控輸入或操作記錄

- GX90YD數位輸出模組:警報輸出

- GX90WD數位輸入/輸出模組:遙控輸入或操作記錄/警報輸出

- GX90XP脈衝輸位模組:脈衝訊號數據收集,積分計數

- GX90UT PID控制模組:PID控制(2迴路)

PID 控制

- 啟用PID和程式控制(每個系統最多20個循環)

- 網路應用程式支援從瀏覽器進行遠端操作和監視。

- 設定點程式控制功能(最多99個模式)

雙重測量範圍

- 使用者可以在單個GM系統上選擇兩個不同的掃描間隔。

可擴充性

- 每個系統最多420點數

- 隨插即用模組

使用方便 *

- 網路連線設定

- 網路同步查看即時資料

行動裝定

- 藍牙

- 手機應用

可靠性

- 安全的資料儲存

- 高精度測量

- 自動填入功能(GA10資料記錄軟體)

降噪設計

- 電磁式繼電器模組

支援21 CFR Part 11(選配)

- 支援美國FDA 21 CFR Part 11(用於製藥)。

支援12到28 VDC電源

- 支援12至28 VDC電源,因此您也可以在汽俥內使用它。

多批次功能(選配)

- 記錄器預先定義的Channel組,用於獨立的啟動/停止控制分隔數據文件。

SLMP通訊(三菱PLC)(選配)

- 可以在沒有sequence的情況下從GM連接到三菱電機PLC的協議功能。

OPC-UA伺服器(選配)

- 可以透過主機系統(OPC-UA客戶端)的乙太網連接GM收集的數據。

支援航空熱處理應用AMS2750 / NADCAP

- 校正時間表控制功能(選配)用於週期性執行校正配定等的時間表管理。

* 關於SMARTDAC +系列網路瀏覽器的Java Plug-in注意事項

關於 OpreX

OpreX是橫河電機工業自動化(IA)和控制業務的品牌。 OpreX代表橫河電機與客戶共同創造價值的卓越技術和解決方案,並涵蓋橫河電機的整個IA產品,服務和解決方案。 OpreX品牌包括以下五個類別:OpreX 轉型化,OpreX 控制,OpreX 測量,OpreX 執行和OpreX 生命週期。 無紙記錄器GX10 / GX20是OpreX資料收集產品系列的一部分,與OpreX測量保持計術同步。 OpreX 測量包含高精度測量,資料收集和分析的現場設備和系統。

橫河電機將透過OpreX品牌理念及技術提供滿足特定需求的整合解決方案,並協助客戶轉型和拓展業務。

Details

為未來做好準備

新增模組增加channel

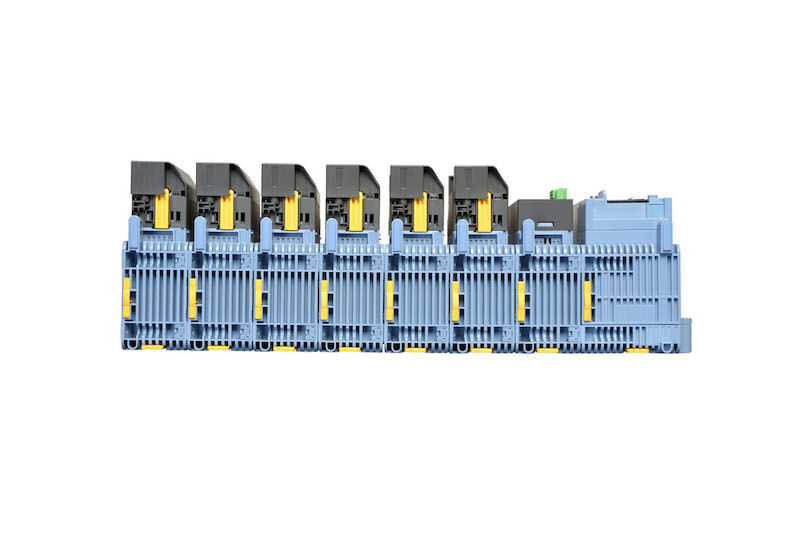

YOKOGAWA 特有的模組結構[專利技術]

- 一次展開一個或多個模組

- 獨特的設計將模組連接到模組底座

- 確保模組底座結合(也可選擇使用滑動鎖和安裝螺釘)

- 可以從前面板插入/卸下模組,維護簡便

資料收集模組零件名稱

標準配備支援最高100 ch的測量(單機配定)

最多10個I / O模組可以連接到單個資料收集模組(GM10)

可安裝在任何地方

多種I / O模組選擇

根據您的應用選擇模組。 並提供抗干擾電磁繼電器類型。 所有模組都有可拆卸的接線端子,接線方便。 SMARTDAC+TM 系列使用相同的模塊。

| 型號 | 名稱 | 測量/應用 | Channel |

|---|---|---|---|

| GX90XA-10-U2 | Analog input module | DC voltage, DC current (with external shunt resistor connected), thermocouple, RTD, contact (solid state relay scanner type) | 10 |

| GX90XA-10-L1 | DC voltage, DC current (with external shunt resistor connected), thermocouple, contact (Low withstand voltage solid state relay scanner type) | 10 | |

| GX90XA-10-T1 | DC voltage, DC current (with external shunt resistor connected), thermocouple, contact (electromagnetic relay scanner type) | 10 | |

| GX90XA-10-C1 | DC current (mA) (solid state relay scanner type) | 10 | |

| GX90XA-10-V1 | DC voltage, DC current (with external shunt resistor connected), thermocouple, contact (Solid state relay scanner type) | 10 | |

| GX90XA-04-H0 | DC voltage, DC current (with external shunt resistor connected), thermocouple, RTD, contact (individual A/D type) | 4 | |

| GX90XA-06-R1 | 4-wire RTD, 4-wire resistance(solid state relay scanner type) | 6 | |

| GX90YA | Analog output module | Current output (isolated between channels) | 4 |

| GX90XD | Digital input module | Remote control input or operation recording | 16 |

| GX90YD | Digital output module | Alarm output | 6 |

| GX90WD | Digital input/output module | Remote control input or operation recording/alarm output | DI:8/DO:6 |

| GX90XP | Pulse input module | Pulse signal data acquisition, integral count | 10 |

| GX90UT | PID control module | PID control (2 loop) | AI:2/AO:2 DI:8/DO:8 |

Analog input module scan interval and measurement type

| Type | Channels | Scan interval (shortest) | Scanner | TC | RTD | DCV | DI | mA | Resistance | Feature |

|---|---|---|---|---|---|---|---|---|---|---|

| Universal (-U2) | 10 | 100ms | SSR | √ | √ | √ | √ | Universal | ||

| Low withstand voltage relay (-L1) | 10 | 500ms | SSR | √ | √ | √ | Mid-price | |||

| Electromagnetic relay (-T1) | 10 | 1s | Relay | √ | √ | √ | Noise-resistance | |||

| DC current input (-C1) | 10 | 100ms | SSR | √ | mA only | |||||

| High withstand voltage (-V1) | 10 | 100ms | SSR | √ | √ | √ | High withstand voltage | |||

| High speed universal (-H0) | 4 | 1ms | — | √ | √ | √ | √ | High speed measurement | ||

| 4-wire RTD (-R1) | 6 | 100ms | SSR | √ | √ | 4-wireRTD |

Internal memory and max. I/O channels

| Type | Internal memory | Max. input/output channels* | |

|---|---|---|---|

| GM10-1 | 500 MB | Single-unit configuration | 0 to 100 |

| Multi-unit configuration | 0 to 100 | ||

| GM10-2 | 1.2 GB | Single-unit configuration | 0 to 100 |

| Multi-unit configuration | 0 to 420 | ||

Actual values support high precision measurement

| Input type | Measuring accuracy*1 (typical value*2) | |

|---|---|---|

| DCV | 20 mV | ±(0.01% of reading + 5 μV) |

| 60 mV | ±(0.01 % of reading +5 μV) | |

| 6 V (1-5V) | ±(0.01% of reading + 2 mV) | |

| TC*3 | R, S | ±1.1 °C |

| B | ±1.5 °C | |

| K (-200.0 to 1370.0°C) | ± (0.01% of rdg +0.2°C for 0.0 to 1370.0°C; ± (0.15% of rdg +0.2°C) for -200.0 to 0.0°C | |

| K (-200.0 to 500.0°C) | ± 0.2°C for 0.0 to 500.0°C; ± (0.15% of rdg +0.2°C) for -200.0 to 0.0°C | |

| J | ± 0.2°C for 0.0 to 1100.0°C; ± (0.10% of rdg + 0.2°C) for -200.0 to 0.0°C | |

| T | ± 0.2°C for 0.0 to 400.0°C; ± (0.10% of rdg + 0.2°C) for -200.0 to 0.0°C | |

| N | ± (0.01% of rdg + 0.2°C) for 0.0 to 1300.0°C; ± (0.22% of rdg + 0.2°C) for -200.0 to 0.0°C | |

| RTD | Pt100 (-200.0 to 850.0°C) | ±(0.02% of rdg + 0.2°C ) |

| Pt100 (-150.00 to 150.00°C) | ±(0.02% of rdg + 0.16°C ) | |

透過多個模組擴充點數,支援最高420 ch(實際輸入)的測量(多單元配定)

使用GX90EX擴充模塊可擴充到420 ch。(GM10-2)

若使用GM10-2大容量類型,當包括MATH和通訊點數時,可用高達1000 ch記錄。 使用LAN網路連接設備以進行分散安裝。

不需使用集線器或中繼器即可直接連接LAN網路。

* 您也可以連接GX60擴充模組。

分佈式安裝減少佈線

當資料記錄器安裝在異地(遠離DUT)時,您可以將子單元放定在現場並監控數據,而無需熱電偶和其他sensor的長距離佈線。

輕鬆導覽

從網路瀏覽器輕鬆連結

可透過網路瀏覽器即時監控GM和更改設定,輕鬆建立零死角且低成本的遠端監控系統,不需要其他軟體。

即時監控

使用滾動軸,可以在過去和當前趨勢間任意滾動。

使用網路覽器線上輸入設定

透過設定螢幕將AI點數設定和其他資訊複製到Excel進行編輯。 編輯後,您可以將數據資料重新匯入設定螢幕。

趨勢,數位和其他即時顯示

專用軟體(免費下載)用於讀取曲線圖和GM設定

通用檢視 viewer

可以查看和列印保存在GM上的文件檔案。 您可以對特定區域執行統計計算並匯出為ASCII,Excel或其他格式。

離線設定軟體

儲存設定或傳輸到GM。 也可以用USB或藍牙輕鬆連接。

可在各種溫度下安全使用

工作溫度為-20°C至60°C,可支援各種應用,無需擔心安裝環境。

可以在平板電腦完成監控和設定

支援藍牙(可選代碼/ C8)

可從平板電腦輸入設定或監視器,不用將電腦帶到現場。 專用應用程式提供免費下載。 詳情請瀏覽我們的網站

使用藍牙啟用監控

藍牙僅支援Android。

透過Wi-Fi啟用監控

Wi-Fi支援Android和iOS。

強大的應用程式

藍牙連接

俥內測試簡便。

USB 連接

維修人員可以輕鬆維護GM。

資料分析變得簡單且行動化

高速測量(最低1毫秒)

Yokogawa的專利 A/D 轉換器可讓高速模組最快1毫秒測量資料點數。

- 高速測量 (1毫秒) *

- 專利A/D 轉接頭

* 每個模組1ch,2毫秒時每個模組2 ch,5毫秒以上時每個模組4 ch。

| 型號 | 掃描間隔 | ||

|---|---|---|---|

| 1毫秒 | 5毫秒 | 10毫秒 | |

| GM10-1 | 1ch | 5ch | 10ch |

| GM10-2 | 5ch | 25ch | 32ch |

雙間隔測量,具有兩個不同的掃描間隔

使用者可以在單個GM系統上選擇兩個不同的掃描間隔,因此可以在單個系統中以兩個不同的掃描間隔測量各種類型的輸入。 例如有效同時測量溫度之類緩慢波動的訊號,或是壓力和振動之類的快速變化的訊號。 可以將模組分配給測量群組。

PID 控制功能

控制功能

啟用PID和程式控制

- PID控制模組

每個模組2個迴路,每個系統最多20個迴路 - 設定點程式控制功能(/ PG選配)

最多99個pattern

遠端操作和監控

網路應用程式支援從瀏覽器遠端操作和監視。

MATH (including reports), and event actions

MATH function (/MT option)

Supports various kinds of math computation, including basic math and functions (square root, logarithms, trigonometry). Write formulas using variables for measured or computed data and save or display the results—this saves time and effort on post-processing. Create hourly, daily, monthly, and other reports with the Report function.

Event actions

Ability to assign actions tied to specific events during the operation of the data acquisition station.

Aerospace Heat Treatment Supports heat treatment application AMS2750/NADCAP

Calibration correction schedule control function (/AH option)

Schedule management for periodically executing calibration correction configuration and the like. You can set the input correction factor as a sensor correction factor and instrument correction factor. TUS software is available for easily creating TUS (temperature uniformity survey) reports.*

* For details on TUS software, consult with your Yokogawa dealer.

Input calibration is performed in the AI channel setting screen, and the calibration period settings are entered in the schedule management setting screen.

Record data in separate files per equipment set

Multi-batch Function (/BT option)

Record pre-defined channel groups to separate data files with independent start and stop control. You can create up to 12 batches.

Report creation and network functions (/MT option)

提供多種方便的網路功能

Modbus / TCP和Modbus / RTU通訊

GM 支援乙太網通訊的Modbus TCP / IP client端和伺服器模式以及用於選配串列通訊的Modbus RTU主從模式(Master-Salve)。

Modbus/TCP (乙太網連結)

使用Modbus / TCP和Modbus / RTU功能,您可以在GM上顯示和儲存來自伺服器和附屬設備的數據。

* 需具有通訊點數 (/MC 選配 )

(最多可連接16個Modbus / TCP伺服器, GM10-2可連接最多32個伺服器)

(最多可連接31個Modbus / RTU slave站)

Modbus/RTU (RS-422/485連線)

使用Modbus / TCP和Modbus / RTU功能,您可以從上游設備收集GM資料數據。

EtherNet/IP 功能(/ E1選配)

GM支援EtherNet / IP伺服器功能,可以從PLC或其他設備連結GX並讀取測量/ MATH點數或寫入通訊輸入點數*(GM10-1: 最多 300 ch, GM10-2: 最多 500 ch).

* 需要通訊點數功能(/ MC選配)。

CC-Link系列SLMP 通訊 (/E4選配)

Protocol 協議功能,無需Sequencer程序記錄器即可從GM連結到三菱電機PLC。 您可以將GM作為SLMP client端運行,將GM測量數據寫入PLC並將PLC數據寫入通訊點數。

* 需要通訊點數功能(/ MC選配)。

收集功率測量儀器上的數據資料(/E2 和/ MC選配)

與功率測量儀器(WT系列功率分析計)數位通訊連接收集GM上的精確數字數據,並記錄與GM的數據。 由於同時記錄設備的功耗,溫度和其他現象,因此GM是性能評估測試的理想選擇。

- 可以連結接的型號:

Yokogawa Test & Measurement Corp.,

WT1800/WT1800E (command type WT1800), WT500, WT300/WT300E (command mode WT300) - 最大連線數: 16

OPC-UA 伺服器 (/E3 選配)

可以透過主機系統(OPCUA client端)的乙太網通訊存取GM的收集數據。 從上游系統寫入GM通訊點數需要通訊點數功能(/ MC選配)。

與DARWIN相容的通訊方式

GM支援DARWIN通訊指令。 在GM上使用您的DARWIN通訊程式。可輕鬆從現有的DARWIN設備進行切換。

* 有關詳細內容,請聯絡我們。

CENTUM/STARDOM 通訊套裝

- CENTUM: LFS2432, DARWIN/DAQSTATION Communication package (適用 ALE111 [乙太網])

- STARDOM: NT365AJ DARWIN connection package

FTP-based文件傳輸

TFTP client/server功能可輕鬆共享和管理來自文件伺服器中心的數據資料。

E-mail 訊息功能

GM 可以發送各種電子郵件,包括警報通知,定期即時數據資料,計劃報告和其他訊息。

自動網路設定(DHCP)功能

使用動態主機設定協議(DHCP),GM可以自動收集DHCP伺服器進行網路通訊所需的設定(IP地址)。 這使得在工廠網路上安裝設備變得前所未有的簡單。

網路時間同步伺服器

GM 在客戶端模式下使用SNTP協議從網路時間伺服器收集時間訊息。 該功能允許設施內任意數量的GM模組具有精確同步的時間; 所有模組都將記錄同步後的日期和時間標記的數據。 此外,GM可以作為伺服器,為網路上其他SNTP客戶端單元提供時間數據。

堅固耐用的硬體和高度安全性

放心保存數據記錄

支援長時間和多點紀錄。 測量數據儲存在內部記憶體,數據定期傳輸到外部儲存媒體。 使用FTP客戶端功能將數據發送到伺服器可以實現冗餘。 即使在突然斷電的情況下,也能安全無虞保存資料。

| 記錄點數數量 | 總採樣時間 |

|---|---|

| 30 | Approx. 71 days |

| 100 | Approx. 23 days |

| 300 | Approx. 7 days |

內建記憶體1.2 GB,記錄間隔為1秒。

根據您的應用選擇文件格式

為了提高安全性,可以以二進位格式檔儲存測量數據。 在傳統的文件編輯器或其他程式,很難破解或修改。 選擇文件格式可以在文件編輯器或電子表格程序中輕鬆直接打開數據, 無需專用軟體即可處理測量數據。

ASCII 資料顯示

二進位資料顯示

安全性增強

安全地發送和接收客戶數據。

SSL: 透過TCP / IP網路傳輸的加密數據。

支援21 CFR Part 11 (/AS 選配)

透過擴充的安全功能選項,儀表支援美國FDA的Title 21 CFR Part 11法規(針對製藥業)。 可以連結憑證的登錄功能,電子簽名,稽核追朔,防篡改功能,Active Directory的密碼管理功能,登錄功能和其他功能。

鍵盤鎖

可透過設定鎖定GM10操作鍵,以避免意外啟動/停止測量或計算。

類比前端模組

獨特的A / D轉換器可提供高速,高精度的資料收集。 (高速AI,PID控制模組)

支援多種標準

GX90XA : Analog input module

Specifications

| Model | GX90XA | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Input type (Inputs: 10) | DC voltage*1, standardized signal*1, thermocouple*1, RTD*2, DI*1, DC current (with external shunt resistor)*1, DC current*3, resistance*4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| DCV | 20 mV, 60 mV, 200 mV, 1 V, 2 V, 6 V, 20 V, 50 V, 100 V*5 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Standard signal | 0.4-2 V, 1-5 V | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Resistance | 20, 200, 2000 Ω | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Thermocouple | R, S, B, K, E, J, T, N, W, L, U, W97Re3-W75Re25, KpvsAu7Fe, Platinel 2, PR20-40, NiNiMo, W/WRe26, N(AWG14), XK GOST | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| RTD | Pt100, JPt100, Cu10 GE, Cu10 L&N, Cu10 WEED, Cu10 BAILEY, Cu10 (20°C) α=0.00392, Cu10 (20°C) α=0.00393, Cu25 (0°C) α=0.00425, Cu53 (0°C) α=0.00426035, Cu100 (0°C) α=0.00425, J263B, Ni100 (SAMA), Ni100 (DIN), Ni120, Pt25, Pt50, Pt200 WEED, Cu10 GOST, Cu50 GOST, Cu100 GOST, Pt46 GOST, Pt100 GOST, PT500*4, PT1000*4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| DI | Level, Contact | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| DC current | 0-20 mA, 4-20 mA | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Scan intervals | 1/2/5/10/20/50/100/200/500ms, 1/2/5s Scan interval by type

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Power supply and consumption | Supplied from main unit, power consumption: 2 W or less | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Insulation resistance | Between input circuits and internal circuitry: 20 MΩ or greater (at 500 V DC) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Withstand voltage | Between the input circuits and the internal circuitry: 3000 VAC for one minute (current input type and low withstand voltage type: 1500 VAC for one minute, high withstand voltage type: 3700 V AC for one minute) Between analog input channels: 1000 V AC for one minute (excluding b terminals for universal input type) (low withstand voltage type: 400 VAC for one minute, high speed universal type: 3000 V AC for one minute) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Terminal types | M3 screw terminals or clamp terminals | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Weight | Approx. 0.3 kg | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

*1 Cannot be set for the current input type (type suffix code: -C1) or 4-wire RTD/resistance type (type suffix code: -R1).

*2 Cannot be set for the current input type (type suffix code: -C1), electromagnetic relay type (type suffix code: -T1), low withstand voltage type (type suffix code: -L1) or high withstand voltage type (type suffix code: -V1).

*3 Can only be set with current input type (type suffix code: -C1).

*4 Can only be set with 4-wire RTD/resistance type (type suffix code: -R1).

*5 Can only be set with high speed universal type (type suffix code: -H0).

Model and Suffix Codes

| Model | Suffix Code | Description | ||||

|---|---|---|---|---|---|---|

| GX90XA | Analog input module | |||||

| Number of channels | -04 | 4 channels (-H0 type only) | ||||

| -06 | 6 channels (-R1 type only) | |||||

| -10 | 10 channels (-C1, -L1, -U2, -T1, -V1) | |||||

| Type | -C1 | Current, scanner type (isolated between channels) | ||||

| -L1 | Low withstand voltage DCV/TC/DI, scanner type (isolated between channels) | |||||

| -U2 | Universal, Solid state relay scanner type (3-wire RTD b-terminal common) | |||||

| -T1 | DCV/TC/DI, Electromagnetic relay scanner type (isolated between channels) | |||||

| -H0 | High speed universal, individual A/D type (isolated between channels) | |||||

| -R1 | 4-wire RTD/resistance, scanner type (isolated between channels) | |||||

| -V1 | DCV/TC/DI, high withstand voltage scannertype (Isolated between channels) | |||||

| - | N | Always N | ||||

| Terminal form | -3 | Screw terminal (M3) | ||||

| -C | Clamp terminal | |||||

| Area | N | General | ||||

GX90YA : Analog output module

Specifications

| Model | GX90YA |

|---|---|

| Output type (outputs: 4) | Transmission output, manual output |

| Range | 4–20 mA or 0–20 mA |

| Output update interval | 100 msec (shortest) |

| Load resistance | 600 Ω or less |

| Resolution | 0.002% |

| Power supply and consumption | Supplied from main unit, power consumption: 3W or less |

| Insulation resistance | Between output circuits and internal circuitry: 20 MΩ (at 500 VDC) |

| Between output channel terminals: 500 VDC, 20 MΩ or greater | |

| Withstand voltage | Between output circuits and internal circuitry: 1500 AC for one minute |

| Between output circuits: 500 VAC for one minute | |

| Terminal type | M3 screw terminals or clamp terminals |

| Weight | Approximately 0.2 kg |

Model and Suffix Codes

| Model | Suffix Code | Description | ||||

|---|---|---|---|---|---|---|

| GX90YA | Analog output module | |||||

| Number of channels | -04 | 4 channels | ||||

| Type | -C1 | Current output (isolated between channels) | ||||

| - | N | Always N | ||||

| Terminal form | -3 | Screw terminal (M3) | ||||

| -C | Clamped terminals | |||||

| Area | N | General | ||||

GX90XD : Digital input module

Specifications

| Model | GX90XD | |

|---|---|---|

| Input types (Inputs: 16) | DI or pulse input*1 (Open collector or non-voltage contact) | |

| ON/OFF detection | Open collector: Voltage of 0.5 V DC or less when ON, leakage current of 0.5 mA or less when OFF Non-voltage contact: Resistance of 200 Ω or less when ON, 50 kΩ when OFF | |

| Contact rating | 12 V DC, 20 mA or more | |

| Power supply and consumption | Supplied from main unit, power consumption: 0.7 W or less | |

| Insulation resistance | Between input terminals and internal circuitry: 20 MΩ or greater (at 500 V DC) | |

| Withstand voltage | Between input terminals and internal circuitry: 1500 V AC for one minute | |

| Terminal types | M3 screw terminals or clamp terminals | |

| Weight | Approx. 0.3 kg | |

Pulse input specifications*1

| Counting system | The rising edge of the pulse is counted. |

|---|---|

| Max. pulse period | 250Hz (The chattering filter : OFF) 125Hz (The chattering filter : ON) |

| Minimum detection pulse width | Low (close), High (open), both is 2 ms or more |

| Pulse detection period | 1ms |

| Pulse measurement accuracy | ± 1 pulse |

| Pulse count interval | Measurement interval |

| Filter | The chattering filter can be switched On/Off. (When the chattering filter is off, connect GX/GP so that it is not affected by the noise.) |

*1 Integration requires the math function (optional code /MT).

Model and Suffix Codes

| Model | Suffix Code | Description | ||||

|---|---|---|---|---|---|---|

| GX90XD | Digital input module | |||||

| Number of channels | -16 | 16 channels | ||||

| Type | -11 | Open collector/Non-voltage, contact (shared common), Rated 5 VDC | ||||

| - | N | Always N | ||||

| Terminal form | -3 | Screw terminal (M3) | ||||

| -C | Clamp terminal | |||||

| Area | N | General | ||||

GX90YD : Digital output module

Specifications

| Model | GX90YD |

|---|---|

| Output types (outputs: 6) | Relay contact (c contact) |

| Rated load voltage | 100 to 240 V AC or 5 to 24 V DC |

| Max. load voltage/current | 264 VAC or 26.4 VDC, 3A/point (resistance load) |

| Power supply and consumption | Supplied from main unit, power consumption: 1.4 W or less |

| Insulation resistance | Between output terminals and internal circuitry: 20 MΩ (at 500 VDC) |

| Withstand voltage | Between output terminals and internal circuitry: 3000 V AC for one minute |

| Terminal types | M3 screw terminals |

| Weight | Approx. 0.3 kg |

Model and Suffix Codes

| Model | Suffix Code | Description | ||||

|---|---|---|---|---|---|---|

| GX90YD | Digital output module | |||||

| Number of channels | -06 | 6 channels | ||||

| Type | -11 | Relay, SPDT(NO-C-NC) | ||||

| - | N | Always N | ||||

| Terminal form | -3 | Screw terminal (M3) | ||||

| Area | N | General | ||||

GX90EX : Expansion module

Model and Suffix Codes

| Model | Suffix Code | Description | ||||

|---|---|---|---|---|---|---|

| GX90EX | I/O expansion module | |||||

| Port | -02 | 2 Ports | ||||

| Type | -TP1 | Twisted pair cable | ||||

| - | N | Always N | ||||

| Area | -N | Standard accessories | ||||

GX90WD : Digital input/output module

Specifications

| Model | GX90WD | |

|---|---|---|

| Input types (Inputs: 8) | DI or pulse input*1 (Open collector or non-voltage contact) | |

| ON/OFF detection | Open collector : Voltage of 0.5 V DC or less when ON, leakage current of 0.5 mA or less when OFF Non-voltage contact : Resistance of 200 Ω or less when ON, 50 kΩ when OFF | |

| Contact input rating | 12 VDC, 20 mA or more | |

| Output type (outputs: 6) | Relay contact (C contact) | |

| Rated load voltage | When connected to the main circuit (fi rst-order power supply), 150 VAC or less When connected to a circuit derived from the main circuit (second-order power supply), 250 VAC or less (the main circuit is 300 VAC or less and uses an isolated transformer) or 30 VDC or less | |

| Max. load current | 2 A (DC)/2 A (AC), resistive load | |

| Power consumption | 1.9 W or less | |

| Insulation resistance | Between input terminals and internal circuitry: 20 MΩ or greater (at 500 VDC) Between output terminals and internal circuitry: 20 MΩ or greater (at 500 VDC) | |

| Withstand voltage | Between input terminals and internal circuitry: 1500 VAC for one minute Between output terminals and internal circuitry: 3000 VAC for one minute | |

| Terminal types | M3 screw terminals | |

| Weight | Approx. 0.3 kg | |

Each unit (GX/GP main unit and expandable I/O), can use 1 module only.

Pulse input specifications*1

| Counting system | The rising edge of the pulse is counted. |

|---|---|

| Max. pulse period | 250Hz (The chattering filter : OFF) 125Hz (The chattering filter : ON) |

| Minimum detection pulse width | Low (close), High (open), both is 2 ms or more |

| Pulse detection period | 1ms |

| Pulse measurement accuracy | ± 1 pulse |

| Pulse count interval | Measurement interval |

| Filter | The chattering filter can be switched On/Off. (When the chattering filter is off, connect GX/GP so that it is not affected by the noise.) |

*1 Integration requires the math function (optional code /MT).

Model and Suffix Codes

| Model | Suffix Code | Description | ||||

|---|---|---|---|---|---|---|

| GX90WD | Digital input/output module | |||||

| Number of channels | -0806 | 8 channel DIs, 6 channel DOs | ||||

| Type | -01 | Open collector/non-voltage contact (shared common), rated 5 VDC; Relay, SPDT, (NO-C-NC) | ||||

| - | N | Always N | ||||

| Terminal form | -3 | Screw terminal (M3) | ||||

| Area | N | General | ||||

GX90XP : Pulse input module

Specifications

| Model | GX90XP |

|---|---|

| Number of inputs | 10 |

| Measurement interval | 100 ms (shortest) |

| Input type | Contact (open collector, voltage-free contact), level (5 V logic) |

| Input range | Up to 20 kHz* * 30 Hz when the chattering filter is in use (On) |

| Minimum detection pulse width | 25 μs* * 15 ms when the chattering filter is in use (On) |

| Measurement accuracy | Count ± 1 pulse During integration, the following accuracies are added. Upon MATH start: +1 measuring period Upon MATH stop: -1 measuring period * Integration requires the math function (optional code /MT). |

| Chattering filter | Removes chattering up to 5 ms (can be turned on/off on each channel) |

| Hysteresis width | Approx. 0.2 V |

| Contact, transistor rating | Contact: 15 V DC or higher and 30 mA or higher rating. Minimum applicable load current 1 mA or less. Transistor: With the following ratings: Vce > 15 VDC, Ic > 30 mA |

| Maximum input voltage | ±10 V DC |

| Insulation resistance | Between input terminals and internal circuitry: 20 MΩ or greater at 500 V DC |

| Withstand voltage | Between input terminals and internal circuitry: 1500 V AC for 1 minute |

Model and Suffix Codes

| Model | Suffix code | Description | ||||

|---|---|---|---|---|---|---|

| GX90XP | Pulse input module | |||||

| Number of channels | -10 | 10 channels | ||||

| Type | -11 | DC voltage/open collector/non-voltage contact (shared common), rated 5 VDC | ||||

| — | N | Always N | ||||

| Terminal form | -3 | Screw terminal (M3) | ||||

| -C | Clamp terminal | |||||

| Area | N | General | ||||

GX90UT : PID control module

Specifications

| Model | GX90UT | |

|---|---|---|

| Control loops | Number of loops | 2 |

| Analog input (measured input) | Measured points | 2 |

| Measurement type | DC voltage (DCV)/standardized signal, TC/RTD, DI (LEVEL and non-voltage contact)/DC current (with external shunt resistance) | |

| Scan (control) interval | 100 ms or 200 ms (system global setting) | |

| Analog output (control output/transmission output/sensor power supply) | Outputs | 2 |

| Output type | Power supply for current, voltage pulse, or sensors. | |

| Current output: 4-20 mA or 0-20 mA | ||

| Voltage pulse output: ON voltage = 12 VDC or more (load resistance 600 Ω or more), OFF voltage = 0.1 VDC or less | ||

| Can be used as a sensor power supply (13.0-18.3 VDC) | ||

| Digital input (switching the SP, operation mode, etc.) | Inputs | 8 |

| Input format | Non-voltage contact and open collector | |

| Contact rating: 12 VDC or more, 20 mA or more | ||

| Digital output (of alarms, events, etc.) | Outputs | 8 |

| Output format | Open collector (sink type) | |

| Output contact capacity | Max 24 VDC, 50 mA | |

| Withstand voltage/insulation resistance | See PID control module general specifications (GS 04L51B01-31EN) | |

| Terminal type | M3 screw terminals | |

| Weight | Approximately 0.3kg | |

Model and Suffix Codes

| Model | Suffix Code | Description | ||||

|---|---|---|---|---|---|---|

| GX90UT | PID control module | |||||

| Number of loops | -02 | 2 loops | ||||

| Type | -11 | 8 DIs, 8 DOs | ||||

| — | N | Always N | ||||

| Terminal form | -3 | Screw terminals (M3) | ||||

| Area | N | General | ||||

-

【Support Information】List of Verified SD Memory Cards (SD Cards)

The SD cards of the following manufacturers have been verified for use with SMARTDAC+ GX/GP/GM, μR10000/μR20000 and FX1000. However, please note that Yokogawa does not guarantee normal operation of the SD card when using with products listed below.

-

【Support Information】List of RoHS

This is a list of recorder and controller products that support the RoHS (2011/65/EU) directive.

-

【Support Information】New Legislative Framework (NLF) Conforming Products

This is a list of recorder and controller products that support the New Legislative Framework (NLF.)

參考

Improving manufacturing efficiency demands constant action - from uncovering operational waste to identifying areas for continuous improvement. Namely, we must always pursue a cycle of visualizing, analyzing, and solving energy saving challenges.

The SMARTDAC+ GM is best suited for applications where the voltage of each cell in fuel cells, secondary batteries and electrolyzers is measured.

Power monitoring package SMARTDAC+ GM and UPM100 system measures and quantifies the electrical energy consumption for each assembly line.

Controls temperature in, and acquires data from, various internal components of plastic film manufacturing equipment. An easy to use, high cost-performance data acquisition and monitoring system can be assembled by using Ethernet compatible instruments and GA10.

the VZ20X installed near sensors such as temperature, humidity, and vibration, and enables automatic collection of data via the factory LAN. The data collection, monitoring and management can be automatically and regularly monitored with the data logging software GA10. As a result, it contributes to reducing the workload of workers.

Caustic soda and hydrochloric acid, produced in electrolyzer plants, are fundamental materials used in varieties of industries; chemicals, pharmaceuticals, petrol-chemicals, pulp and papers, etc. Profit is the result of the effective production with minimized running / maintenance cost. Proper control of the process brings you stabilized quality of products with the vast operational profit.

Customers want to improve maintenance by predicting failures of existing durable equipment. However, existing equipment do not have enough space, and it is not easy to increase the number of sensors needed to grasp the condition.

To address this issue, the VZ20X’s compact size allows it to be installed between equipment, and data collection can be easily monitored via Ethernet (Modbus/TCP).

AN 04L51B01-02EN

AN 04L51B01-03EN

The GX20 and GX90UT offer an average value computation function making it ideal for controlling temperature and other fluctuating phenomena. The operating status can be controlled in real time, providing operating cost reductions.

Customers want to improve maintenance by predicting failures of existing durable equipment. However, existing equipments do not have enough space, and it is not easy to increase the number of sensors needed to grasp the condition.

To address this issue, the VZ20X’s compact size allows it to be installed between equipments, and data collection can be easily monitored via Ethernet (Modbus/TCP).

AN 04L51B01-01EN

Industrial hydrogen fuel cells can be used to produce hydrogen and oxygen from distilled water as well as run in reverse to generate electricity. Fuel cells can also be used in conjunction with intermittent energy sources like solar or wind to provide regulated continuous energy output.

The SMARTDAC+ GM is used extensively for data acquisition in various kinds of conveyance equipment including automobiles, industrial vehicles, in-plant vehicles, ocean shipping vessels, and automated materials handling systems. In addition to being compact and not requiring a PC for data acquisition, the SMARTDAC+ GM can be run under DC power and be operated under harsh conditions (-20° to 60°).

In semiconductor manufacturing processes, a deficient clean room environment can lead to defects and wasted resources, making a strictly controlled clean room indispensable. Maintaining the environment in the clean room requires control of air filters, HVAC systems, room temperature, humidity, airborne particles, and other factors.

The SMARTDAC+ GM10 is employed by customers who are device manufacturers when they deliver a device to the end user, for on-site monitoring to check that the delivered device is operating stably. If settings are made to the SMARTDAC+ GM10 in the office beforehand, then all that is necessary is to take it to the site and begin data acquisition thus, anyone can conduct on-site data acquisition.

- For remote monitoring (of temperature, pressure, and flow volume), installing the SMARTDAC+ GM in the plant and the SMARTDAC+ GX in the office provides for a scalable, pc-free on-site data monitoring solution.

- You can centralize management of large quantities of data by automatically transferring acquired data to a FTP server.

Data acquired on the SMARTDAC+ GM can be easily monitored through the company network, even from remote locations.

In durability testing of engines, revolutions and load control signals are applied and the results are acquired on a recorder. Using the Data Acquisition System SMARTDAC+ GM's PID control module, you can record data while simultaneously applying control signals.

下載

產品型錄

- SMARTDAC+ Data Acquisition & Control Data Acquisition System GM (8.2 MB)

- SMARTDAC+ series Easy connection to PROFINET devices (787 KB)

- SMARTDAC+ Advanced Security Function Data Integrity Support for pharmaceutical & medical standards (2.0 MB)

- SMART 920, 920 MHz band wireless communication instrument series (For US market only) (6.3 MB)

- AI Product Solution Book Download

- SMARTDAC+, the best-selling paperless recorder (data logger), now supports PROFINET! (1.3 MB)

- SMART 920, 920 MHz band wireless communication instrument series (For the Republic of Korea) (7.1 MB)

- Power monitoring package SMARTDAC+ GM / UPM100 (2.4 MB)

操作手冊

- Precaution on the use of SMARTDAC+ (615 KB)

- Data Acquisition System GM First Step Guide (9.4 MB)

- Data Acquisition System GM User's Manual (13.9 MB)

- SMARTDAC+ STANDARD IP Address Configurator (782 KB)

- Model GX10/GX20/GP10/GP20/GM10/GX90NW PROFINET Communication User's Manual (4.5 MB)

- Cloud Equipment/Quality Predictive Detection Tool User’s Manual (166 KB)

- Model GX10/GX20/GP10/GP20/GM10 Communication Command User's Manual (4.4 MB)

- Handling of the SD Memory Card (321 KB)

- SMARTDAC+ STANDARD Hardware Configurator User's Manual (4.4 MB)

- SMARTDAC+ STANDARD Universal Viewer User's Manual (4.1 MB)

- Regarding the Downloading and Installing for the Software, Manuals and Labels/About the Usage of Open Source Software (367 KB)

- GX20/GP20 (/CM2 and /CM3 options), GM10 (/CM2, /CS2, /CM3 and /CS3 options) 920MHz wireless communication First Step Guide_US,KR (1.3 MB)

- Data Acquisition System GM Advanced Security Function (/AS) User's Manual (3.9 MB)

- Model 773230 Downloading the Validation Documents (132 KB)

- Model GX10/GX20/GP10/GP20/GM10 Multi-batch Function (/BT) User’s Manual (3.5 MB)

- Model GX10/GX20/GP10/GP20/GM10 EtherNet/IP Communication (/E1) User’s Manual (1.8 MB)

- Model GX10/GX20/GP10/GP20/GM10 WT Communication (/E2) User’s Manual (1.5 MB)

- Model GX10/GX20/GP10/GP20/GM10 OPC-UA Server (/E3) User’s Manual (884 KB)

- Model GX10/GX20/GP10/GP20/GM10 SLMP Communication (/E4) User's Manual (2.1 MB)

- Model GX20/GP20/GM10, UT52A/UT32A, UPM100 920 MHz Wireless Communication, MH920 Console International (For the US and the Korea) (11.6 MB)

- Model GX10/GX20/GP10/GP20/GM10 Log Scale (/LG) User’s Manual (1011 KB)

- Model GX10/GX20/GP10/GP20/GM10 Loop Control Function, Program Control Function (/PG Option) User’s Manual (23.6 MB)

- Notes on using the Model GX90EX expansion module (I/O expansion module) (194 KB)

- *Discontinued: Data Acquisition System GM Integration Bar Graph Function (/WH) (2.0 MB)

產品規格

- Data Acquisition System GM (3.6 MB)

- GX60 I/O Base Unit (Expandable I/O), GX90EX Expansion Module (3.1 MB)

- GX90XA/GX90XD/GX90YD/GX90WD/GX90XP/GX90YA I/O Modules (4.6 MB)

- GX90UT PID Control Module, GX10/GX20/GP10/GP20, GM, Loop Control Function, Program Control function (/PG) (1.8 MB)

- Equipment/Quality Predictive Detection Tool (340 KB)

- GX20/GP20 (/CM2 option) GM (/CM2 and /CS2 options) 920MHz Wireless Communication (2.3 MB)

- Model 773230 Validation Document for SMARTDAC+ (for the /AS option) (335 KB)

- List of the US Toxic Substances Control Act (TSCA) Compliant Recorder and Controller Products (175 KB)

- 415940, 415941 and 415942 Shunt Resistor for Screw Input Terminal (178 KB)

- 438920, 438921 and 438922 Shunt Resistor for Clamp Input Terminal (252 KB)

- List of the US Toxic Substances Control Act (TSCA) Compliant Recorder and Controller Products (175 KB)

- List of RoHS (2011/65/EU) Directive Compliant Products (6-substances RoHS compliant products) (356 KB)

- New Legislative Framework (NLF) Conforming Products (362 KB)

- Model code selection tool for Power monitoring package SMARTDAC+ GM / UPM100

軟體下載

- Hardware Configurator *Log-in Required

- Universal Viewer *Log-in Required

- IP Address Configurator for GM10 *Log-in Required

- GA10 Data Logging Software *Log-in Required

- GA10 Data Logging Software [60-day free trial] *Log-in Required

- Offline version: Equipment/Quality Predictive Detection tool OE10 *Log-in Required

- Validation Document for SMARTDAC+ *Log-in Required

- EtherNet/IP Profile (EDS file) for GM10 *Log-in Required

- PLC Communication Protocol Profile (EDS file) for GM10 (For connecting OMRON's PLCs) *Log-in Required

- SMARTDAC+ Report Template Builder *Log-in Required

- SMARTDAC+ Excel Report Simulator *Log-in Required

- SMARTDAC+ SettingFileConverter Settings File Conversion Tool *Log-in Required

- Mobile WEB Application for GX/GP/GM *Log-in Required

- GM Mobile Tool *Log-in Required

- SD Card Formatter *Log-in Required

- USB Driver for GM10 *Log-in Required

- LabVIEW Driver (for SMARTDAC+ Series) *Log-in Required

- GM10 Firmware *Log-in Required

- SMARTDAC+ I/O Module Firmware *Log-in Required

- SMARTDAC+ I/O Expansion Module Firmware *Log-in Required

- SMARTDAC+ PID Control Module Fiemware *Log-in Required

- MH920 Wireless Communication module (Router) Firmware *Log-in Required

技術訊息

- Data Acquisition System Introduction to the Various Features of the GM (2.8 MB)

- Effectively Using SMARTDAC+; Software Introduction (6.1 MB)

- SMARTDAC+ GM Advanced Security Functions White Paper for FDA 21 CFR Part 11 (503 KB)

- Reduce Risk by Eliminating Paper Chart Records (1.6 MB)

- DARWIN Replacement Guide (9.1 MB)

- High-speed Measurement Application High-speed Measurement/ Dual Interval Measurement Feature LR Replacement (8.9 MB)

- Recorders, Data Loggers, and Control Products Security Standard (488 KB)

- DAQMASTER Replacement Guide (4.2 MB)

- SMARTDAC+ Loop Control Function, Program Control Function (/PG Option) (9.5 MB)

認證證明

產品外型圖

- Analog Input Module GX90XA (531 KB)

- Expandable I/O GX60 (575 KB)

- SMARTDAC+ GM Data Acquisition System (1.8 MB)

- Analog Output Module GX90YA (265 KB)

- Pulse Input Module GX90XP (329 KB)

- Digital Input/Output Module GX90WD (229 KB)

- Digital Output Module GX90YD (267 KB)

- Digital Input Module GX90XD (378 KB)

- Expansion Module GX90EX (207 KB)

影片

Smart user interface, smart architecture, and smart functionality is achieved in the Yokogawa SMARTDAC+ data acquisition and control product series.

SMARTDAC+ consists of the GX and GP touch screen data acquisition stations and the most recent addition – the GM data acquisition and data logging system which is both compact and modular.

新聞

-

新聞 2018年7月5日 橫河電機開發高壓模擬輸入模組,加入OpreX數據採集產品陣容

-

新聞 2022年4月19日 SMARTDAC+無紙記錄器和資料收集器專用品質檢測工具

-不是 AI 專家也可以為工廠建構自己的設備和品質異常檢測系統-

想了解更多技術&解決方案嗎?

聯絡我們