Robot and Drone Solutions for plant safety and efficiency

Plant operators face challenges such as sustaining a stable workforce, enhancing worker safety, and achieving data-driven plant operations. Yokogawa provides Robot and Drone Solutions for a safer and more efficient operation.

Autonomy in Harmony – Orchestrating Synergy Across Humans, Robots, and Drones

As a one-stop solution provider, Yokogawa enables the adoption of robots and drones, which supports plant control across the customer value chain to achieve autonomous operations, while embodying the concept of “Autonomy in Harmony” in your day-to-day operations.

To accelerate the achievement of unattended operations, Yokogawa leverages more than 100 years of process automation expertise, to expand the robot and drone business and systems capability, for a total integrated, purpose-built application suite.

Our solutions are evolving every day.

If a headline catches your interest, click to learn more.

Yokogawa Collaborates with Shell on Robotics and AI Technology for Plant Maintenance

Yokogawa Enters into Sales Partnership with Sensyn Robotics for Drone-Related Services

Details

Customer Challenges

The common challenges in routine inspections and maintenance activities today include:

- Safety Risks: Due to working at height in exposed structures, hazardous areas or harsh environments. All requiring extra protection and work processes.

- Labor Shortages: Due to the aging population and technical skills gap.

- Limited Information: Due to the limitation of human capabilities to acquire and process data accurately and efficiently.

Solutions

Yokogawa’s Robot Solutions

Yokogawa’s Robot Solutions bring together Yokogawa’s expertise in process automation combined with the advanced robot technologies to help the customer achieve unattended operations, whilst also augmenting human capabilities to solve the common challenges in daily plant operations and routine inspections.

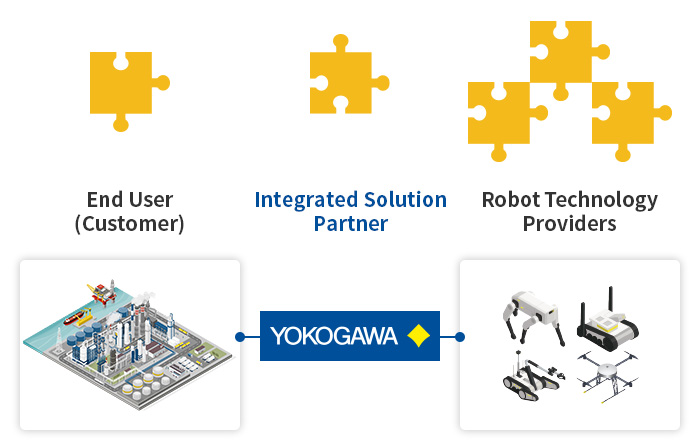

One-stop Solution Provider

Yokogawa provides a one-stop solution that consists of continuous activities through the three steps: Consulting, Implementation, and Operation and Maintenance. Ensuring the reliability, availability, and continuous improvement of the robot solutions’ value to the customer.

Consulting: Problem definition, best-suited solution, hardware and software selection.

Implementation: Use case development and solution engineering.

Operation and Maintenance: After-sales service that ensures the availability of the solutions, finding new challenges, and collaboratively developing new use cases that will increase the value of the solution over time.

OpreX Robot Management Core

OpreX Robot Management Core facilitates the integration of multiple robots, manages data collected by them, and expands the range of applications that contributes to the customer’s business. OpreX Robot Management Core is a part of Yokogawa Collaborative Information Server (CI Server) that integrates the complex hierarchy composed of various systems, to unlock critical process data required to achieve data-driven optimization.

To learn more about OpreX Robot Management Core, please click here.

Robot Fleet Management: Coordinate, Collect, and Control

The foundation for remote operations and fully autonomous operations, is the integrated control and monitoring of multiple robots, with a single integrated Human Machine Interface (HMI). This provides access from multiple devices for the ease of fleet coordination, control and data collection.

Data Management: Aggregate, Analyze, and Report

Data aggregation from multiple devices is a difficult task. This platform manages the complex data and communication structures, enabling further analysis and reporting. Furthermore, we can also add AI applications to analyze the data captured by the robots.

OpreX Plant Image Analyzer is an AI application developed by Yokogawa, which provides AI image analysis for captured images to give meaningful insights.

To learn more about OpreX Plant Image Analyzer, please click here.

Interface with Other Systems

Yokogawa’s interface achieves seamless data integration with other systems, such as AI applications and third-party software.

Integration with Existing Control System and Asset Management System

Implementation of robots is a new way to conduct business for most customers. Where integration with their existing system, such as control and asset management system, will be a new challenge.

Yokogawa’s domain knowledge and expertise in process automation and IT/OT technology enables a seamless integration process that will bring unattended operations to reality.

Benefits

By leveraging Yokogawa’s one-stop solution and expertise in process automation and IT/OT technologies, customers can move forward to the implementation of robots with a peace of mind and avoid the new technology becoming another silo in the organization. By enabling seamless integration process, unattended operations becomes a reality.

Implementing the appropriate use cases of robot solutions for the specific problem that is defined through consulting has the capabilities to bring:

- Safety Improvements by reaching dangerous areas quickly, easily, and safely.

- Strengthened Workforce by allowing the emerging workforce to use technology to do tasks more efficiently. And as a result, the customer will be able to focus on value creation tasks.

- Insightful data, brings the right data to the right viewers (e.g. the decision makers). The robots can be equipped with sensors and specifically designed payloads to meet operational objectives.

Use Cases

Field Patrol

Field patrol with robots offers enhanced efficiency, continuous monitoring capabilities, and improved safety for personnel. Whilst there are also challenges presented in relations to technology integration, maintenance, and ethical considerations.

- The robots perform routine surveillance tasks at field autonomously, at a scheduled time and on demand.

- Robots become the “eyes,” “ears,” and “nose” of the plant with a combination of different sensors to detect anomalies and monitor the assets with AI analysis.

Color Degradation Diagnosis Using Robot with AI Solution

A color degradation diagnosis system employs a robot integrated with an AI image analyzer to assess objects for color changes. The sensors capture data on hue and brightness, which AI algorithms interpret to diagnose degradation severity. The system then flags items for maintenance, offering fast and accurate assessments to preserve object quality and value.

First Responder Solution

In emergency situations, deploying robots as first responders offers numerous advantages. Including the support for operators to assess the situation, gather critical data, and execute tasks such as deactivating equipment or assisting in rescue efforts.

- With the robot integration platform and DCS, the robots continuously provide real-time feedback to the command center, enabling responders to formulate effective strategies and mitigate safety risks.

Infrastructure Inspection Solution with Drones

Implementing an infrastructure inspection solution with drones can significantly enhance efficiency, safety, and accuracy.

-

Safe and efficient monitoring of power transmission grid with drones

Enhance power transmission safety with drones for fast, efficient monitoring and reduced risks.

-

Efficient detection of oil tank corrosion and leaks with drones

Prevent oil leaks and corrosion with early detection using drones for efficient maintenance.

-

Maintaining solar panel efficiency with drones

Maintain solar panel efficiency with regular drone inspections to detect damage early.

-

Safe and secure wind turbine blade inspection with drones

Increase safety and efficiency by using drones to inspect wind turbine blades without high-altitude risks.

-

Efficient and sustainable forest management with drones

Promote sustainable forestry with drones for efficient monitoring and early disease detection.

-

Ensure safety by reducing gas leakage risk with drones

Protect workers and the environment by detecting gas leaks early using drones with gas sensors.

-

Efficient facility monitoring with robot patrols

Achieve stable plant operations with robots for regular patrols and early anomaly detection.

-

Rapid and efficient equipment degradation diagnosis with robots

Use robots to detect equipment degradation early, minimizing unplanned downtime and maintenance costs.

Downloads

Brochures

- Robot and Drone Technology (1.3 MB)

Videos

Nieuws

-

Persbericht | Oplossingen en Producten October 28, 2024 Yokogawa gaat sales partnership aan met Sensyn Robotics voor drone-gerelateerde diensten

Voor veilige en efficiënte inspecties van fabrieken en andere infrastructuur over de hele wereld

-

Laatste Nieuws April 17, 2024 Sterk staaltje teamwork met robothonden ANYmal en Spot

-

Persbericht | Oplossingen en Producten March 26, 2024 Yokogawa lanceert OpreX Robot Management Core

Complete uitrol van robot operations-oplossing voor meer veiligheid en efficiëntie op productielocaties

Op zoek naar meer informatie over onze mensen, technologie en oplossingen?

Contact