Las necesidades de las empresas petroquímicas son muy diversas. Para salir adelante en el mercado altamente competitivo de hoy, los productores se esfuerzan por mejorar la calidad y la productividad. Yokogawa ofrece soluciones a su medida para estas necesidades con base en su larga y amplia experiencia en este campo.

Desafíos

El reto de los clientes

Las fluctuaciones en los precios de las materias primas y en la oferta y demanda de productos hacen que sea absolutamente esencial optimizar la planificación de la producción.

Nuestras soluciones

Yokogawa ofrece un sistema de gestión de la producción que cierra la brecha entre la planificación y la manufactura, para hacer posible una programación idónea de los procesos de producción de petroquímicos.

Tecnología instrumental

Real‐time Production Organizer™ : RPO

Real‐time Production Organizer™ (RPO) es un paquete de aplicaciones de plataforma desarrolladas específicamente para cerrar la brecha entre la planificación de la producción y el control de procesos, proporcionando un entorno de producción empresa a procesos (B2P) totalmente integrado.

Las soluciones para la gestión de la producción de Yokogawa ayudan a que las operaciones obtengan más ingresos por planta y crean un puente entre los sistemas de procesos en tiempo real y los sistemas corporativos.

El reto de los clientes

Para mantener la competitividad en el mercado global, la optimización de los procesos en todas las áreas de una planta no es menos necesario que el desarrollo de una oferta de productos competitiva que satisfaga necesidades específicas de los usuarios.

Nuestras soluciones

Yokogawa provee soluciones de automatización en toda la planta que permiten el control ágil y flexible de los flujos de trabajo de la producción de petroquímicos y que están totalmente integradas a un sistema instrumentado de seguridad.

Tecnología instrumental

Sistema de control de la producción: CENTUM VP

El sistema de control integrado CENTUM VP garantiza un desempeño de la planta "solo tiempo de actividad" sin interrupciones para lograr una productividad y rentabilidad óptimas.

Sistema instrumentado de seguridad: Prosafe‐RS

El sistema instrumentado de seguridad ProSafe‐RS permite soluciones verdaderamente integradas y suministra al mismo tiempo la alta disponibilidad que se requiere para aplicaciones con niveles de integridad de la seguridad 1 al 4 (SIL 1‐4).

vigilantplant services.®

vigilantplant services.® es un paquete de servicios integrales que hacen realidad el concepto VigilantPlant de Yokogawa, el cual ayuda a los fabricantes a conseguir que las operaciones en sus plantas sean seguras, confiables, respetuosas del medio ambiente y rentables.

El control de procesos avanzado (APC) y la optimización en línea logran operaciones más rentables en una planta petroquímica. Las soluciones están disponibles para plantas de etileno, polietileno, polipropileno y aromáticos.

El gestor de recursos de la planta (PRM) facilita el mantenimiento predictivo. La detección temprana de fallas en sistemas y dispositivos puede ayudar a prevenir una falla catastrófica.

Las cámaras de monitoreo compactas, de alto rendimiento y a prueba de explosión son un ejemplo del compromiso de Yokogawa por construir instrumentos de campo confiable que son capaces de resistir hasta los ambientes más severos. Se utilizan en una planta petroquímica para monitorear las operaciones de día y de noche.

El reto de los clientes

Las plantas petroquímicas consumen enormes cantidades de energía, de manera que las iniciativas para el ahorro de energía en estos centro de producción pueden ayudar en gran medida a alcanzar la competitividad en costos y reducir las emisiones de CO2 que contribuyen al calentamiento global. Una estrategia clave para lograrlo es optimizar el control del proceso de producción.

Nuestras soluciones

Los avanzados sistemas de control de procesos de Yokogawa hacen posible que las plantas operen con una mayor eficiencia, reduciendo así el consumo de energía y las emisiones de CO2.

Tecnología instrumental

Software basado en soluciones

Información operativa integrada, validada y oportuna que respalda las iniciativas de mejora continua y la optimización del rendimiento productivo.

Los sistemas analíticos con gran capacidad de respuesta contribuyen a una medición precisa de propiedad de producto/intermedio y la combustión a base de calderas/hornos, ayudando a las compañías petroquímicas a cumplir normas más estrictas de control de calidad y ambientales.

Recursos

- Stable operation and proactive maintenance were realized at new coal-chemical plant in China.

- Yokogawa engineers ensured a successful and efficient commissioning and startup.

Yokogawa provided an integrated and comprehensive solution for ethylene cracking process optimization.

SMOC APC controller improved control level of ethylene cracking unit and reduced operators workload.

- La Excelencia Operativa a través de la Maximización de Activos, utilizando DCS, SIS, Analizadores, y los Instrumentos de Campo de Yokogawa

- El CENTUM VP PCS y ProSafe-RS SIS se integraron utilizando el mismo entorno de ingeniería.

- Casi 60 cromatógrafos de gases y un gran número de otros tipos de analizadores en varias casas analizadores.

- Using the CENTUM CS 3000 system, many kinds of plant key performance indexes are calculated and analyzed to produce further improvements.

- During plant start-up, PRM helps the customer's engineers perform all the loop checks.

- Yokogawa provides CENTUM CS 3000, Exaquantum and PRM solutions for China's largest refinery/petrochemical complex.

- Process data management by Exaquantum is a key issue in the petrochemical complex.

- Sistema de Paro de Emergencia Certificado

- Reducción sustancial de los trabajos de mantenimiento

- La configuración del sistema con espacio reducido

- Las etapas del sistema

- Cumplir con las normas funcionales de seguridad IEC 61508/JIS C 0508

- Proactivamente introducir tecnologías de vanguardia

- Adaptarse a las licencias de la planta, los requisitos de seguridad, confiabilidad y de mantenimiento

- Mejorar las funciones de monitoreo y operación del sistema de paro de emergencia

Samsung Petrochemical Co. Ltd. (SPCL), a major Korean petrochemical company, produces 700,000 tons per year of purified terephthalic acid (PTA) at its Daesan plant. PTA, a white powder substance that is produced by oxidizing and refining para-xylene, is a precursor to polyethylene terephthalate (PET), a polyester material that has excellent thermal resistance and wear resistance and is widely used as a substitute for natural cotton fibers and in film packaging, beverage bottles, tire cords, paints, adhesives, and other applications.

- Migración del sistema de plantas de Polietileno y Petroquímica de PetroChina Dushanzi.

- La renovación incluyó la desafiante creación de las especificaciones de diseño de función (FDS), así como las pruebas FAT y SAT.

- Implementation of multivariable optimizing controllers and robust quality estimators within a record short period

- 3% rise expected in CCR feed amount

- ABS plant migrates from CENTUM XL to integrated CENTUM CS 3000 solution.

- CENTUM CS 3000 Integrated Production Control System together with CCTV equipment, a plant information management system (PIMS), the Exaplog Event Analysis Package, and the CS Batch 3000 package.

- 16,000 FOUNDATION Fieldbus devices

- Main Automation Contractor (MAC)

- DCS anywhere concept integration with site SAP system

- Long term maintenance contract

- Sustainable development

- All logistics of raw materials, intermediate products and final products are controlled and managed by MAS.

- MAS enables Operational Excellence with its seamless interface to enterprise resource planning system.

- Exapilot automates comlex and non-routine decoking process of NCUs.

- Operator workload has been drastically reduced.

- Cambio en un día

- Mejora de la productividad y la rentabilidad

- A Japanese petrochemical plant leverages FDT/DTM-compliant intelligent field devices and Yokogawa's PRM asset management system for maintenance efficiency.

- The customer aims to improve maintenance efficiency further by introducing condition-based maintenance (CBM).

- Yokogawa assisted in the project implementation by providing design review, calculation modifications, pre-commissioning, training of operators and engineers, commissioning and post implementation review.

- Shell Global Solutions and Shell Deer Park Management were completely satisfied with the way the project was implemented and with the results achieved.

- The Advanced Process Control application implemented on the Scotford MEG unit helped control the plant with less variation, resulting in maximized TEG production and reductions in overall steam consumption.

- TEG production increases were greater than originally estimated and the prices for steam and TEG used in the post-implementation study were reduced significantly.

In the plants of food and beverage manufacturers, there are times when monitoring and recording of production equipment is necessary inside clean rooms. This is an introduction to monitoring and recording in clean rooms using paperless recorders.

Prevent costly downtime and process equipment failures with real-time pressure monitoring. Yokogawa’s Sushi Sensor is the optimal choice for industries depending on bottled gas in essential procedures.

The GX20 and GX90UT offer an average value computation function making it ideal for controlling temperature and other fluctuating phenomena. The operating status can be controlled in real time, providing operating cost reductions.

Enhance the efficiency and safety of your vapor recovery systems and flare/vent headers with Yokogawa's cutting-edge Tunable Diode Laser Spectrometers – the TDLS8000 and TDLS8220. Elevate your oxygen measurement capabilities with our interference-free analyzers, providing direct measurements. Experience unparalleled reliability, ensuring minimal upkeep and secure operations without the need for system shutdowns.

La configuración del transmisor de nivel puede tomar mucho tiempo. Los transmisores DPharp tiene la función de un software avanzado eliminando esta tarea que toma tiempo. Con talleres de mantenimiento cada vez más pequeños, la búsqueda de equipos que nos permiten hacer más con menos se convierte en una prioridad.

The Yokogawa DTSX1 Fiber Optic Heat Detector protects your equipment against abnormal heat events while being more affordable than other heat detection solutions.

In limestone-gypsum flue gas desulfurization systems, the consumption of a desulfurization agent (lime) is controlled using online pH analyzers.

Fired heaters are used for various processes in oil refining and petrochemical plants.

Both bulk and finished inventories are stored in distributed tank farm remote from the site operations. These are difficult to instrument due to the infrastructure cost involved. These are then monitored daily by patrol rounds. While effective, this method does require a large skilled labor force to monitor all of tanks. This can impose an additional risk when the stored medium is of a hazardous nature.

Install a YTMX580 on the side of the rotating furnace that can wirelessly transmit measured values from multiple temperature sensors.

- Temperature is monitored to maintain consistency of the viscous fiber entering the drum.

- Existing system requires manual temperature readings.

- Wired temperature measurement is not available because the tank is rotating.

- Wireless temperature measurement

Gateway x1, transmitter (YTA) x1, repeater x2 (The 2 repeaters are for redundancy) - Extended antenna to circumvent obstacles and improve the radio path for stable measurement (communication was unstable when the height of the antenna was low).

ISA100 wireless temperature and pressure transmitters with orifice plates allow:

- No cabling installations or maintenance.

- Small amount of hardware and simple equipment implementation means minimizing potential vandalism.

ISA100 Wireless Monitoring

- Gateway x1, Temperature Transmitter (YTA) x3, Pressure Transmitter (EJX) x1, Repeater x1

Gateway is installed at control room and 3m height extended antenna is set.

- Temperature Transmitter (YTA) and Pressure Transmitter (EJX) are installed at each monitoring point.

- Repeater is installed on high position.

Wastes have been considered to be a serious worldwide environmental problem in recent years. Because of increasing pollution, these wastes should be treated. However, industrial wastes can contain a number of valuable organic components. Recovery of these components is important economically. Using conventional distillation techniques, the separation of acetic acid and water is both impractical and uneconomical, because it often requires large number of trays and a high reflux ratio. In practice special techniques are used depending on the concentration of acetic acid.

Liquefied Petroleum Gas (LPG), or also known as LP Gas or auto gas, is a mixture of hydrocarbon gases used as a fuel in heating appliances and vehicles, and increasing replacing chlorofluorocarbons as an aerosol propellant and a refrigerant to reduce damage to the ozone layer.

Pressure measurement of tubeless tyres to monitor the air loss is one of the key performance tests in the tyre manufacturing units. Relocation of tyres from one testing rack to the other for various tests and frequent movement of the testing setup for conditional tests to various locations calls for cable free implementation for ease of handling.

In this eBook we explain how to improve fired heaters safety & efficiency by controlling combustion using TDLS technology. Download it now and learn:

- The 4 top industry challenges related to fired heaters

- How to efficiently and safely manage combustion

- How TDLS technology can improve operational excellence in fired heaters

In this Yokogawa RAP Best Practices eBook, you’ll discover how our wealth of knowledge about Integrated Safe Systems and Control of Work is available to help you and your teams design and implement a system that best suits your needs.

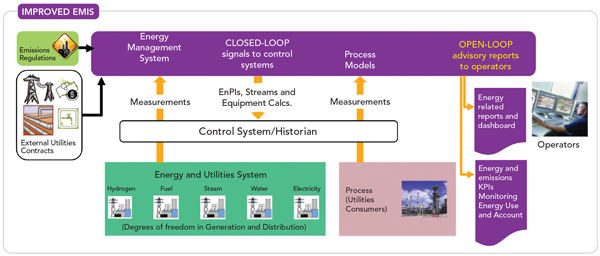

Visual MESA© is a steam system optimization and management computer program that was originally developed at Chevron and now marketed by Nelson & Roseme, Inc. Visual MESA is currently used at refinery and chemical manufacturing sites to optimize the overall site steam system and the parts of the electrical system that economically trade off with the steam system.

This paper will explore significant optimization variables and constraints commonly encountered in refinery steam system optimization, the strategies Visual MESA uses to deal with them.

In general, refineries exhibit a very good potential for real time monitoring and optimization using Visual MESA Energy Management System.

Based on our extensive experience, overall benefit in the range of 2% to 5% of the total energy cost can be achieved. Expected project payback is always less than one year.

Outline

- Introduction

- What is Energy Optimization

- How does a Real Time Online Energy Management System based on Visual MESA work

- Calculation Foundation for Key Performance Indicators

- Visual MESA implementation at Saudi Kayan (A SABIC Affiliate) (SK)

- Optimization Actionable Items

- Economic Benefits

- Relevance of Visual MESA RTEMS for SK's Sustainability Initiative

- Conclusions

Get Connected: Advancing Workers and Capabilities

In this whitepaper by Shahzad Khan, you will learn how to use collaborative, integrated, optimized, and autonomous operations to integrate your systems and emerging performance metrics.

By downloading this whitepaper you will learn how to:

- Connect operations, systems, processes, maintenance, and goals

- Empower employees digitally, to improve their decision-making skills

- Gain access to immediate improvements to production efficiency

This paper will not describe just all the features of the software or fully explain on-line optimization technology. The objective of this work is to present some interesting facts and lessons from the experience of implementing a cost based optimization program at thirty oil refineries and petrochemical complexes, around the world, since 1997. This paper will focus on the key optimization variables and constraints in steam system optimization, how they should be handled and how the human and organizational aspects can be addressed.

Industrial facilities where power and steam is produced (i.e., Cogeneration) exhibit a very good potential for real time monitoring and optimization using Visual MESA Energy Management System.

Based on our extensive experience, overall benefit in the range of 2% to 5% of the total energy cost can be achieved. Expected project payback is always less than one year.

Visual MESA was successfully applied to many industrial facilities worldwide, several of them operating steam and power generation networks of different complexity and capacity but all with energy cost savings.

This paper discusses real industrial examples in which the sitewide utilities system of refinery and petrochemical Sites are optimized with a real time, on line, industrially proven software. Experiences gained during more than 20 years of industrial projects deployed worldwide are commented (Refs. 1 to 10 are related to some recent projects). Main project steps are explained and critical details to be taken into account to assure successful use and proper technology transfer are presented. Specific case studies will be discussed in the paper.

Utilities and energy systems are often the major source of SOx, NOx and CO2 emissions, therefore, emissions control and the management of credits and quotas are tightly interrelated with energy management.

In the case of refineries, chemical and petrochemical plants, energy represents the main cost (second to feedstock) and therefore its reduction has become a bottom line business decision. The energy systems at these sites are inherently complex, with the emissions cost analysis and limits compliance introducing an additional factor to the complexity of the energy costs reduction challenge.

Process plants use different type of fuels, they often operate cogeneration units, their steam networks consist of several pressure levels, there are different types of energy consumers and there are emission limits to be observed. Import or export of electricity in deregulated markets, which could also be traded off with more or less CO2 and other contaminant gaseous emissions, increase the optimization problem complexity.

This paper addresses some of the root causes for issues and discusses the best practices that will help to avoid project failures. Main project steps are explained and critical details to be taken into account to assure successful use and proper technology transfer are discussed. It also presents real industrial examples in which the whole utilities system cost of a production Site (i.e., steam, fuels, boiler feed water and electricity) is optimized with a real time, online, industrially well established software.

Utilities and energy systems are often the major source of SOx, NOx and CO2 emissions, therefore, emissions control and the management of credits and quotas are tightly interrelated with energy management. In the case of refineries, chemical and petrochemical plants, energy represents the main cost (second to feedstock) and therefore its reduction has become a bottom line business decision. The energy systems at these sites are inherently complex, with the emissions cost analysis and limits compliance introducing an additional factor to the complexity of the energy costs reduction challenge.

The energy systems, the steps for the implementation of Visual MESA and several features of the model are described in this article, with a focus on the use of the software for the calculation of energy-related KPIs. The EMS implementation project is discussed and the main conclusions relative to the reduction in operating costs are also presented.

Experiences gained during more than 20 years of industrial projects deployed worldwide are commented. Main project steps are explained and critical details to be taken into account to assure successful use and proper technology transfer are presented. Specific case studies will be discussed in the paper. Open loop vs Closed loop implementation is also presented.

Rohm and Haas Company is one of the world's largest manufacturers of specialty materials, including adhesives, sealants, coatings, monomers, electronic materials, inorganic and specialty solutions, and ion exchange resins. Founded in 1909 by two German entrepreneurs, Rohm and Haas has grown to approximately $6 billion in annual revenues.

Alarm management is not just a project that has a start and end date; it's a continuous cycle. Once the alarm system has been reviewed and improvements have been identified, we must check that controls are in place to ensure the alarm system remains functional. The key is to ensure that the system is continuously monitored and any changes are fully documented. There are seven key steps for alarm management. Rationalization is one of those critical steps.

This paper shows how to improve distillation operations by focusing on procedure automation. It will review the importance of using procedures in distillation operations and highlights the collaboration work underway between Fractionation Research Inc. (FRI) and Yokogawa Corporation to improve procedural operations.

The worlds of process automation and production management have been converging for some time. What once used to be islands of automation and production management functionality connected through highly proprietary integration schemes that were costly to maintain have developed into integrated platforms that provide seamless data exchange between the world of automation and the plant floor, the functions of production and operations management, and integration with business level systems.

The world of process automation is governed by procedures. While we like to refer to the process industries as being largely "continuous", this could not be further from the truth. Process manufacturing is constantly in flux.

From engineering to installation, commissioning, operations, and maintenance, FOUNDATION fieldbus offer significant cost reductions of 30 percent or more versus conventional analog systems. Many of these cost reductions come from the advanced functions that fieldbus offers versus analog technology.

The automation suppliers that will be successful in the long term will be those that effectively address application or industry specific problems for end users with a value proposition that cannot be ignored. These problems exist throughout the process industries today, and they won't be solved by simply offering a product, but through a combination of hardware, software, services, application expertise, and knowledge.

In ARC's view, customers need a compelling business value proposition to justify investment in any kind of automation. Vigilance and VigilantPlant were created with this in mind. Yokogawa's vision with VigilantPlant is to create an environment where plant personnel and operators are well informed, alert, and ready to take action.

Yokogawa ha recorrido un largo camino en hacer que su mensaje sea claro en el mundo de la automatización de procesos. El año pasado, la compañía se embarcó en una campaña global de marketing a gran escala para que los clientes conocieran el enfoque de la compañía en la confiabilidad del sistema, su seguridad, constancia y durabilidad. Denominado "Vigilancia", la campaña creó un mensaje unificado para la empresa y en gran medida ayudó a aumentar la difusión de la marca Yokogawa y la filosofía de la empresa.

Los usuarios finales de procesos automatización están bajo más presión para hacer más con menos. La situación económica actual hace que muchos proyectos de capital de automatización estén en espera. Con los presupuestos de capital más limitados que nunca, los usuarios en lugar de enfocarse en los presupuestos de operaciones (en donde también la reducción de costos es una preocupación clave), o en las inversiones de automatización con un rápido retorno de inversión.

In today's dynamic industrial marketplace, the only constant is change. Raw material costs, energy costs, market demands, environmental and safety regulations, technology, and even the nature of the labor force itself are constantly changing, and not always in predictable directions.

La migración de DCS de una refinería proporcionó una oportunidad para volver a configurar y consolidar las salas de control y sistema de administración operativo.

July 2011

Process plants are run according to operational procedures. These procedures consist of a set of tasks that are executed in a consistent manner to achieve a specific objective, such as starting up, shutting down or transitioning a unit as part of making a product.

September 2008

Yokogawa is helping a large chemicals site in China manage product transfer by road, ship and pipeline.

March 2006

The new CSPC (CNOOC and Shell Petrochemicals Company Limited) petrochemical complex at Daya Bay in southern China is one of the world's largest process industry projects (see box, Figure 1 and Table). It has a control system to match. Process Worldwide spoke to Johan Veerman, principal instrument and process control engineer at CSPC, about the challenges of managing such a huge job.

CONTROL, January 2013

Standard Automation Methodology Improves Operations and Prevents Incidents by Enabling the Sharing of Best Practices Among Operators.

ARC believes that by implementing procedural automation, many process plants can minimize variability to help ensure smooth, efficient, and safe state transitions.

Adding process considerations improves energy savings and production performance.

Documentos y Descargas

Catálogos

- Yokogawa in the Petrochemical Industry (6.3 MB)

- TDLS8220 LOC (Limiting Oxygen Concentration) Infographic

- Extractive Tunable Diode Laser Spectrometer TDLS8220 (5.6 MB)

- Soluciones y Productos Yokogawa en Norteamérica (3.6 MB)

- CENTUM VP DCS Top 10 Features Infographic (231 KB)

- Yokogawa Performance Distillation Solutions

- Overcome Temperature Effects for DP Level (778 KB)

Videos

The YSS1000 setting software (hereinafter referred to as the YSS1000) is package software to configure the functions of the YS1000 series (hereinafter referred to as the YS1000) devices. Writing and reading of parameters and user programs of the YS1000, and PID tuning and monitoring of user programs can be performed through the use of communication.

Chet Mroz, President & CEO Yokogawa North America, discusses the benefits of IoT at the 2015 ARC Industry Forum in Orlando.

Sample systems are a crucial component of and have a significant impact on the performance of a process gas chromatograph analyzer. When working on sample systems, you must have a constant awareness of time delays. This fundamentals webinar will take the mystery out of lag times.

Noticias

-

Nota de Prensa feb 20, 2023 Yokogawa Enters into Partnership with Radial Software Group to Provide AI-powered Viewport Software Worldwide

- Giving customers a single view of all their technical data -

¿En busca de información adicional sobre Yokogawa Iberia, tecnología y soluciones?

Contáctenos