In the agitation process of a chemical plant, raw materials (liquids and powders) supplied by pumps are mixed using an agitator to produce products through chemical reactions. If the supply pump deteriorates and the material supply is unstable, unexpected changes may occur in the production recipe, impacting product quality. Additionally, if the supply of raw materials is stopped, the agitator to run idle, potentially shut-down production due to damage to the motor bearings or couplings.

By appropriately monitoring the condition of supply pumps, deterioration and breakdowns can be prevented, however, it is difficult to monitor a large number of supply pumps deployed in a wide plant with the operator rounds.

Customer Issues

Equipment monitoring with limited man-hours

A chemical plant utilizes a large number of supply pumps, making it difficult to monitor them through operator rounds. Instead of relying on operator rounds carried out by workers, there is a need to automate constant monitoring.

Impact on production quality due to deterioration of supply pumps

To stabilize product quality, it is necessary to detect signs of abnormality in the supply pumps, and perform appropriate maintenance.

Industrial IoT Wireless Solution Sushi Sensor

Online monitoring

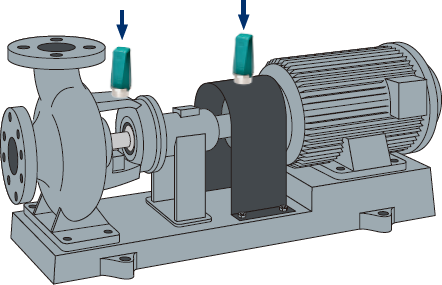

The condition of equipment can be monitored online by utilizing the Sushi Sensor. Wireless vibration sensors are installed on the center of shaft coupling between the motor and supply pump. The condition of the bearings is constantly monitored to detect signs of equipment abnormality (“something wrong”)

Maintaining and improving inspection quality

The collected data can be monitored and recorded using the Data Logging Software GA10 through the LoRaWAN® network. By digitizing the condition of equipment and enabling quantitative judgments based on the collected data, the monitoring system prevents the overlooking of signs of abnormalities. In utilizing GA10's Anomaly Detection Function, the AI detects changes in equipment conditions as signs of abnormality and alerts the user of such signs.

Benefits

By replacing operator rounds of equipment monitoring with the Sushi Sensor, equipment with a high risk of failure can be efficiently identified.

In one case at a chemical plant, the wireless vibration sensor is installed on multiple supply pumps to monitor the condition of equipment online, stabilizing to improved product quality. As a result of the detailed diagnosis of the equipment that exceeded the threshold, bearing wear was detected in the motor, and maintenance was carried out. This enabled the equipment to maintain its health condition and prevented product quality from being impacted. Currently, the temperature of raw material storage tanks, piping and containers are also being monitored by Sushi Sensor, expanding the scope of monitored processes and equipment.

By installing the Sushi Sensor, the entire plant is monitored online to contributes to maintaining the health of equipment and stabilizing product quality.

Example of System Configuration

업종

-

화학

화학 플랜트는 연속 및 Batch 생산 공정에 의존하며, 각각은 제어 시스템에 대한 다양한 요구 사항을 제시합니다. 연속 공정은 실패하지 않고 생산 라인을 중단시키는 견고하고 안정적인 제어 시스템을 필요로하는 반면, Batch 공정의 중요성은 수식, 절차 및 공정을 조정하는 데 있어 큰 유연성을 허용하는 제어 시스템을 갖추는 데 있습니다. 두 종류의 시스템 모두 제품의 사용 가능한 품질 내역에서 관리되어야 하며 비일상적인 작업을 수행할 수 있어야 합니다. Yokogawa는 광범위한 제품 포트폴리오, 숙련된 시스템 엔지니어 및 글로벌 영업 및 서비스 네트워크를 통해 모든 공장 공정에 대한 솔루션을 제공합니다.

Related Products & Solutions

-

무선 압력 센서

이 제품은 배터리로 작동되는 무선 압력 센서의 역할을 하며 산업용 IoT(IIoT) 애플리케이션에 적합합니다. 무선 압력 센서에는 배관 내 가스 및 액체의 게이지 압력을 측정하는 기능이 있습니다.

-

무선 온도 센서

이 제품은 배터리로 작동되는 무선 온도 센서 역할을 하며 산업용 IoT(IIoT) 애플리케이션에 적합합니다. 무선 온도 센서는 2개의 IEC 표준 열전대(thermocouple) 입력을 지원합니다. (유형 B, E, J를 포함한 9 가지 유형)

-

무선 진동 센서

스시 센서는 배터리 구동 무선 진동 센서의 역할을 하며 산업용 IoT (IIoT) 애플리케이션 제품에 적합합니다. 무선 진동 센서는 표면 온도를 모니터링할 뿐만 아니라 X, Y 및 Z축을 따라 진동을 측정합니다.

-

스시 센서

스시 센서는 산업용 IoT (IIoT) 무선 솔루션입니다. 환경 저항성이 뛰어나고 절전 및 장거리 통신이 가능한 저전력 광역 통신망 LoRaWAN을 기반으로 합니다.