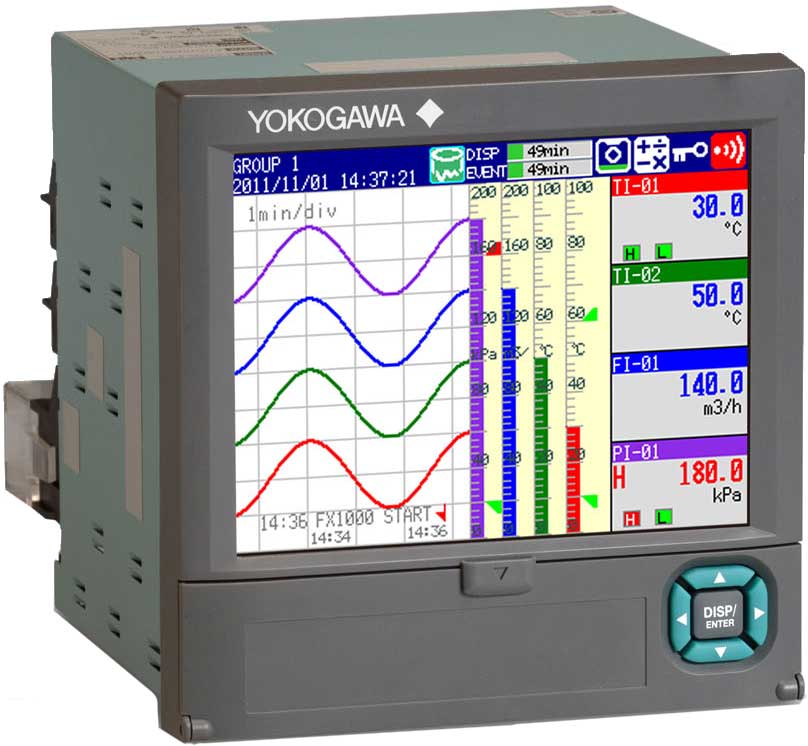

The FX1000 paperless recorder exceeds customer expectations for quality, high performance and capability—at a price that meets the needs of a cost-sensitive market. FX1000 combines a clear view of process data with highly reliable recording and efficient data access. Network file transfer and web browser viewing improves efficiency and saves time. In addition, FX1000 has the ability to monitor power consumption and record energy usage for diagnostic, preventative maintenance and cost savings.

Features

Intuitive display, easy operation

- 5.7-inch, high-precision, wide-viewing-angle color TFT LCD

- Many types of displays such as trend, digital, bar graph, overview, alarm, and historical trend

- Remote viewing of the FX1000 screen through the Internet

- Multi-functional panel keys

- Start/stop recording by batch, and create data files

Comprehensive selection of measurement types, and exceptional performance

- Input types: DCV, TC, RTD, DI

- Scan interval: 1 s, 125 ms (fast sampling)

- Channels: 2, 4, 6, 8, 10, 12

- Measurement accuracy: ±0.05% of reading (DCV), ±0.15% of reading (TC, RTD)

Reliable data storage

- Large (400 MB) internal memory

- SD cards or CF cards, up to 32 GB

- USB interface (option)

- Binary data storage

- Network enables data redundancy

Support for a variety of applications

- Power measurement recording (option)

- Vacuum pressure recording (Log scale, option)

- Flow rate summation (option)

- F value calculation (option)

Reliable design and construction

- Space-saving design

- Waterproof and dustproof (IP65 compliant)

Resources

There are thousands of miles of underground pipelines found in the world today. All pipelines require strategically located pumping stations, most often determined by factors such as pipeline size, topography, land use and local road access. The main purpose of the station is to pressurize the flow of gas along the line, but they can also function as remote monitoring stations. Pipeline inlet and outlet pressure as well as temperature are monitored at each station to confirm the gas is flowing. These stations are typically unmanned and are required by DOT 49 CFR 195.452 "pipeline integrity management in high consequence areas" to be monitored and assessed on a periodic basis.

Downloads

Brochures

- Paperless Recorder FX1000 (8.9 MB)

Instruction Manuals

- FW1000 Regarding the Downloading and Installing for the Software (FXA120 DAQSTANDARD) and Manuals (416 KB)

- FX1000 Safety Precautions and Installation Guide (1.5 MB)

- FXA120 DAQSTANDARD for FX1000 Data Viewer User's Manual (1.7 MB)

- FXA120 DAQSTANDARD for FX1000 Hardware Configurator User's Manual (2.9 MB)

- FX1000 Communication Interface (/C2, /C3, /C7) User's Manual (3.5 MB)

- FX1000 First Step Guide (2.4 MB)

- FX1000 User's Manual (5.3 MB)

- FW1000 User's Manual Safety Precautions and Installation Guide (853 KB)

- How to Use the CD Installing FXA120 DAQSTANDARD and Opening FX1000 Manuals (482 KB)

General Specifications

- New Legislative Framework (NLF) Conforming Products (362 KB)

- List of RoHS (2011/65/EU) Directive Compliant Products (6-substances RoHS compliant products) (356 KB)

- List of the US Toxic Substances Control Act (TSCA) Compliant Recorder and Controller Products (175 KB)

- Paperless Recorder FX1000 (1.6 MB)

- X010 External Precision Resistor (349 KB)

Technical Information

Drawings

- Paperless Recorder FX1000, 2D DWG (1.6 MB)

- Paperless Recorder FX1000 (552 KB)

- Paperless Recorder FX1000, 2D DXF (2.2 MB)

Looking for more information on our people, technology and solutions?

Contact Us