Yokogawa provides optimum solutions to improve the reliable operation of water treatment plants. These solutions include sophisticated technologies, unsurpassed product quality, and extensive application know-how throughout the lifecycle.

Details

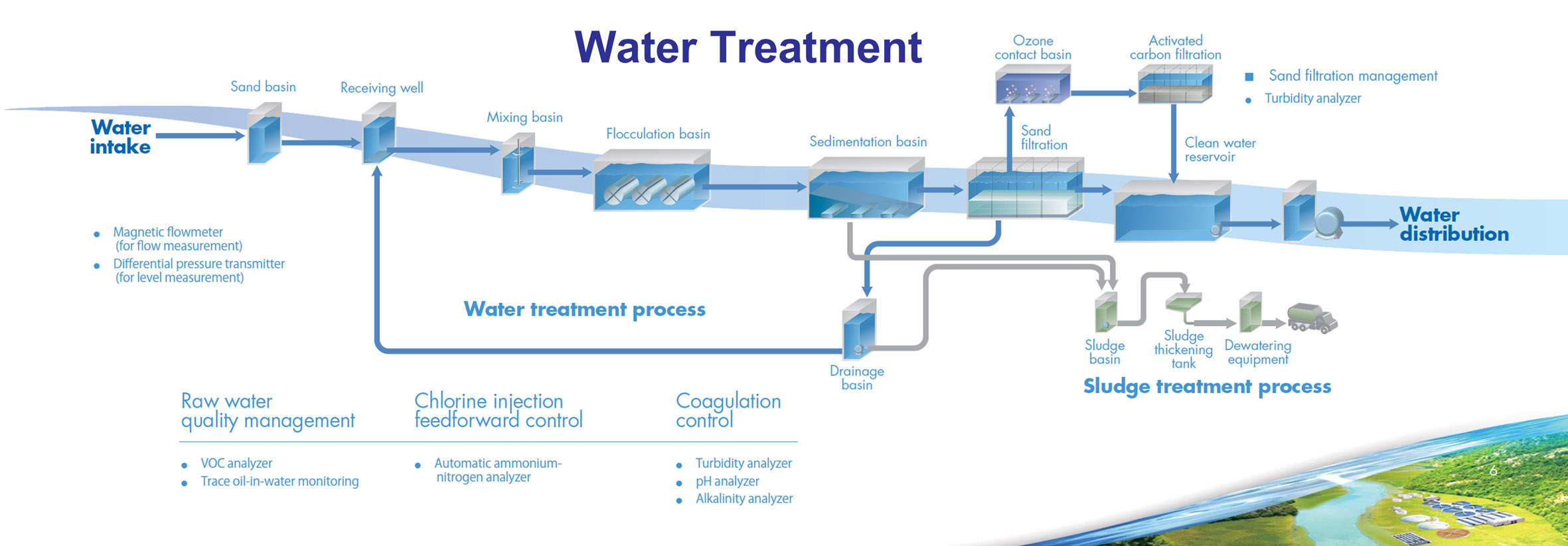

Water Intake

- Raw water quality management

Quick response to accidents at the raw water source and automatic control of hazardous substances using online analysis technology.

Water Treatment

- Raw chlorine injection feed forward control

Estimation of chlorine consumption and injection of optimum amount to ensure that water is safe and good taste. - Coagulation control

The optimization of coagulation control at water treatment plants ensures that the correct amount of coagulant is injected.

Advanced Water Treatment

- Automatic powder injection control

Quick automatic treatment coordinated with raw water quality management.

Automation products

Solution-based Software

- Operation efficiency improvement package: Exapilot

- Event analysis package: Exaplog

- Plant information management system: Exaquantum

- Plant resource manager: PRM

- SCADA/PLC & RTU

- SCADA : Fast/Tools

- PLC & RTU: Stardom, FA-M3

Distributed Control System (DCS)

- DCS: CENTUM VP

Safety Instrumented System (SIS)

- SIS: ProSafe-RS

Data Acquisition & Control Equipment

- Paperless recorders : GX10/GX20, GP10/GP20, DL850E/DL850EV, XL120

- Data acquisition equipment : SMARTDAC+ GX/GP series, Daqstation series

- Temperature controller: UT Series Temperature Controllers

- Digital indicating controller: UP Series Program Controllers, UM Series Digital Indicators with Alarms

- Single-loop controllers: YS1000 Series, YS80 Series

Field Wireless Products

- Field wireless multi-function module : FN510

- Field wireless multi-protocol module: FN310

- Wireless differential pressure/pressure transmitter: EJX B Series

- Wireless temperature transmitter: YTA510

- Multi-input temperature transmitter: YTMX580

- Field wireless management station: YFGW410

- Field wireless access point: YFGW510

- Field wireless media converter: YFGW610

- Field wireless integrated gateway: YFGW710

- Versatile device management wizard: FieldMate

Field Instruments

- Pressure: EJX, EJA series

- Magnetic flowmeter: ADMAG series

- Vortex flowmeter: digitalYEWFLO series

- Coriolis mass flowmeter: ROTAMASS 3-series

- Ultrasonic flowmeter: US300PM, US300FM

- Temperature: YTA Series

- Level transmitter: EJX, EJA series

- Radar level meter: PULS60Y series

- Guided wave radar level meter: FLEX80Y series

- Ultrasonic level meter: SON60Y series

Liquid Analyzers

- pH/ORP analyzer: FLXA402, FLXA202, FLXA21, SENCOM Series

- Conductivity analyzer: FLXA402, FLXA202, FLXA21

- Turbidity analyzer: TB820D, FLXA402T, TB400G

- Dissolved oxygen analyzer: FLXA402, FLXA202, FLXA21

- Chlorine analyzer: FC800D, RC800D, FLXA402T

- MLSS analyzer: SS400

- Liquid density analyzer: DM8

Resources

- More than 1,000 field devices designed to the PROFIBUS specifications installed in the state-of-the-art water reclamation plant.

- The high reliability and accuracy of our field devices contributes to the minimization of maintenance costs over the entire plant lifecycle.

- The aging DCS system was replaced with an integrated control system for all processes at the Siheung water treatment plant.

- Powerful Modbus communication function of STARDOM enables integration with the existing HMI via the OPC gateway.

- To bring the customer a real-time monitoring and management capability, Yokogawa installed STARDOM (FCJ), flow meters, and transmitters at key points throughout the distribution network.

- The STARDOM FCJ controllers achieved an accurate water loss management system while keeping the running costs to a minimum.

Water Supply Treatment

FAST/TOOLS, STARDOM, Flowmeters, Liquid Analyzers

- Bali's water treatment plant decided to employ the latest reliable control system in order to increase availability and quality of operation.

- Centralized control system using FAST/TOOLS provides the sophisticated and flexible operation.

STARDOM field control node (FCN) autonomous controllers allow both Modbus master and slave functions to run simultaneously.

The control of the world's water resource is arguably one of the most important issues. Water demand from industry and domestic users is set to rise throughout the industrialized world. Yokogawa has been applying minimized maintenance measurement systems.

What is screen differential control? This is a control application commonly found at utility plants located on rivers, lakes and other large bodies of water and at industrial facilities where a large amount of cooling water is used. Screen differential control and monitoring is needed to prevent damage to rotating screens caused by excessive pressure being applied by debris collecting on the screens.

The ADMAG AXR is the world's first 2-wire magnetic flow meter which employs the unique "Dual Frequency Excitation Method," achieving 0.5% of rate of best-in-class accuracy and excellent stability for process measurement. In addition, the newly developed AXR key technologies," achieves the same level of noise immunity as 4-wire type under the fluid condition change and delivers enough performance to meet the requirement to apply in the control loop.

Wastewater from electroplating facilities and certain types of chemical plants contains toxic forms of hexavalent chromium such as chromate and dichromate. The hexavalent chromium in this wastewater must be reduced before the water can be discharged. This requires a two-step process: hexavalent chromium (CR6) is reduced to trivalent chromium (CR3); and CR3 is precipitated as chromium hydroxide.

Industry:Electrical and Electronics

Japan's Potable Water Quality Standard was fully revised in 2004, increasing the number of water quality standard items for which tests are required has increased to 50. As items necessary for water quality management, the authority has specified an additional 27 complementary parameters to set the targets for water quality management.

The discharge of improperly treated industrial chemicals and fuel gas can have a major impact on the environment, posing a serious threat to public health. Concurrent with the global growth of manufacturing operations to keep pace with market trends, many countries are taking measures to deal with environmental problems.

Cyanide-bearing wastewater from mining and electroplating facilities and certain types of chemical plants is toxic and must be treated by oxidation with chlorine or chloride to bring the cyanide concentration within regulatory limits.

Industry:Electrical and Electronics

Weir-type flow volume calculation using the M series Free Programmable MXS (or VJXS) Computing Units

Environmental data (water quality, amount of flow) is measured on-site and monitored from an office.

Data acquired on the SMARTDAC+ GM can be easily monitored through the company network, even from remote locations.

When used to measure the dissolved oxygen in an aeration tank, sensors tend to quickly become contaminated and need frequent cleaning.

Taking advantage of sensors already available in your system, you can simply add VJ series signal conditioners or the UM33A Digital Indicator with Alarms to easily build a monitoring system on a PC.

The detectors used to perform dissolved oxygen (DO) measurement in oxidation ditch type sewage treatment plants tend to become dirty quickly and require frequent cleaning.

For nearly 100 years, ozone has been used all over the world for water sanitation. It is nature's strongest oxidizer and has a byproduct of pure oxygen. Chlorine, on the other hand, is a very effective, time-proven chemical, but is ineffective against hard-to-kill microorganisms such as cryptosporidium; it also has some unpleasant byproducts. Ozone is recognized among the strongest, fastest, commercially available disinfectants and oxidants for water treatment, Ozone is used in both the disinfection of drinking water and bacterial killer in waste water treatment. Ozone is used in a large percentage of Municipal water treatment facilities as well as Pharmaceutical companies where pure water is essential.

The worlds of process automation and production management have been converging for some time. What once used to be islands of automation and production management functionality connected through highly proprietary integration schemes that were costly to maintain have developed into integrated platforms that provide seamless data exchange between the world of automation and the plant floor, the functions of production and operations management, and integration with business level systems.

From engineering to installation, commissioning, operations, and maintenance, FOUNDATION fieldbus offer significant cost reductions of 30 percent or more versus conventional analog systems. Many of these cost reductions come from the advanced functions that fieldbus offers versus analog technology.

The automation suppliers that will be successful in the long term will be those that effectively address application or industry specific problems for end users with a value proposition that cannot be ignored. These problems exist throughout the process industries today, and they won't be solved by simply offering a product, but through a combination of hardware, software, services, application expertise, and knowledge.

In ARC's view, customers need a compelling business value proposition to justify investment in any kind of automation. Vigilance and VigilantPlant were created with this in mind. Yokogawa's vision with VigilantPlant is to create an environment where plant personnel and operators are well informed, alert, and ready to take action.

Yokogawa has come a long way in making its message clear to the world of process automation. Last year, the company embarked on a full-scale global marketing campaign to make customers aware of the company's focus on system reliability, security, dependability, and robustness. Dubbed "Vigilance", the campaign created a unified message for the company and greatly helped expand awareness of the Yokogawa brand and corporate philosophy.

Process automation end users are under more pressure than ever to do more with less. The current economic climate means that many automation capital projects are on hold. With capital budgets tighter than ever, users instead focus on operational budgets (where cost cutting is also a key concern), or on automation investments with a very rapid return on investment.

In today's dynamic industrial marketplace, the only constant is change. Raw material costs, energy costs, market demands, environmental and safety regulations, technology, and even the nature of the labor force itself are constantly changing, and not always in predictable directions.

Downloads

Brochures

News

-

Press Release Mar 19, 2025 Yokogawa to Supply Integrated SCADA for Melbourne Water

-

Press Release Jul 27, 2018 Yokogawa to Deliver Statewide Centralized Water Information Management System in India

Looking for more information on our people, technology and solutions?

Contact Us