Elevates Product Quality and Streamlines Manufacturing with Seamless Data Integration and Automated Workflows

Empowers real-time decision-making by integrating EBR, WMS, and LIMS systems seamlessly

Yokogawa's cutting-edge solutions provide seamless data integration and automated workflows, transforming manufacturing processes for optimal performance.

By integrating systems such as Electronic Batch Records (EBR), Warehouse Management Systems (WMS), and Laboratory Information Management Systems (LIMS), we offer a single source of truth that empowers real-time decision-making and enhances overall production quality.

Details

Common Manufacturing Challenges

Isolated systems and manual intervention causes inefficient operation

In a typical manufacturing setup, various systems are isolated and operated in different departments such as quality control, inventory management, and production. Time-consuming manual data entry can lead to:

- Delays in decision-making due to scattered information.

- Increased risk of errors affecting product quality.

Solutions

Achieving seamless operations with automated workflows

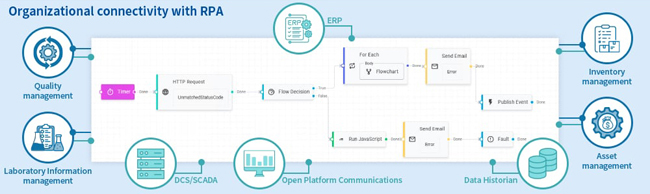

Seamlessly integrate data across critical processes such as Electronic Batch Records (EBR), Warehouse Management Systems (WMS), Quality Management Systems (QMS), and Laboratory Information Management Systems (LIMS).

Key Features That Enhance Manufacturing Efficiency and Quality

Integrated Data Platforms

A unified platform that consolidates data from various systems, ensuring accuracy and consistency.

Automated Workflows

Reducing the need for manual data entry, thereby minimizing errors and saving valuable time.

Enhanced Decision-Making

Real-time data access enables quicker and more informed decisions, improving overall operational efficiency.

Benefits

Transformed Manufacturing Processes

A Closer Look at Our Integrated Workflow Solutions

Raw Material Quality Tracking

- Automated tracking from raw material request to finished product quality inspection.

- Seamless data flow between departments, enhancing traceability and accountability.

Batch Record Management

- Streamlined batch processing with automated data capture and validation.

- Improved compliance with regulatory standards through precise record-keeping.

Quality Event/Deviation Management

- Proactively manage quality data and deviations to reduce production downtime.

- Enhance visibility of quality issues and enable swift corrective actions.

Process

Steps for Implementation

Step 1

Site Survey and Assessment

- Conduct a comprehensive survey to understand existing workflows and systems.

- Identify integration opportunities and areas for improvement.

Step 2

Integration Design and Implementation

- Develop a detailed integration plan, including data interfaces and workflow automation.

- Ensure compatibility across various systems and applications, regardless of the brand.

Step 3

Benefits Realized

- Significant reduction in manual data entry and associated errors.

- Enhanced real-time decision-making capabilities.

- Improved product quality through consistent and accurate data management.

- Greater efficiency in production processes, reducing lead times and operational costs.

Moving Towards Smart Manufacturing

IT/OT Integration Readiness

- Establish a robust infrastructure to support seamless IT/OT integration.

- Ensure long-term success with a solid foundation in data integration and workflow automation.

Real-Time KPI Management

- Simplify KPI development and management with an integrated data platform.

- Improve existing KPIs and create new ones with ease, focusing on quality and efficiency.

Enhanced Product Quality

- Ensure data integrity and traceability across production, quality assurance, and inventory management.

- Provide a single source of truth, reducing production lead time and enhancing overall efficiency.

News

Möchten Sie weitere Informationen über unsere Mitarbeiter, Technologien und Lösungen?

Kontakt