从一个观察者来说,由横河的警戒工厂解决方案管理的炼油厂,看起来“安静且单调”——彼得•德魯克的名言。工厂的盈利能力却能够大幅提高。自动化系统帮助工厂人员管理使用知识,提高生产力并遵守健康、安全和环境法规。在恰当的时间把前后相关的信息清晰地传递给正确的人,让责任人有预见性,冷静、高效地处理突发事件。横河的警戒工厂解决方案帮助所有炼油企业实现“安静且单调”的工厂。

挑战

客户面临的挑战

炼油厂的知识密集型操作,如工厂的启动和关闭、压缩机的启动和原油罐切换,仍然需要由大量操作员手动操作。 比如,有效的原油切换通常需要一套复杂的操作,包括启动/停止马达、打开/关闭阀、流量测量和冲洗等。这通常需要由有经验的操作员按特定顺序执行。

此外,由于有经验的操作人员会退休或离职,因此有必要保留他们的专门知识和做法,并将这些知识准确地传递给非熟练的操作人员。这是至关重要的,以便很大限度地提高生产效率,避免或消除可能由误操作导致的停机。

我们的解决方案

通过使用Exapilot,可以在标准化的程序流程图中将横河基于知识的自动化解决方案、专业知识和操作实践形象化并进行管理和配置。这种标准化的方法不仅实现了复杂操作的自动化,而且保证了每当操作员发生变化或技能水平不同时,有用的专业知识可以被准确地转交和执行。

客户获得的收益

我们的一个客户,是日本的石油、润滑油和石油化工产品的生产商和经销商,他们在一个实验设施中引入Exapilot,据估计,使工时减少了2000个小时*。

客户面临的挑战

在炼油厂可以通过安装高效的设备和更有效地运营来实现节能。横河拥有可以帮助企业提高效率和降低能源消耗的解决方案。

我们的解决方案

自上世纪70年代石油危机以来,日本的炼油业一直通过降低能源消耗和减少二氧化碳排放来应对不断上涨的能源价格和严格的监管。炼油厂经营者通过引进一些技术来实现这一目标,并在这方面得到了横河系统、解决方案和工程能力的支持。横河已经参与了1000多个炼油项目,并在这个行业建立了很好的声誉。横河提供的解决方案,通过提高效率节约能源。

1、能耗的可视化与关键绩效指标(KPI)管理

为了节约能源,减少炼油厂的CO2排放,必须清楚地看到排放和能源消耗的状况。 横河提供了广泛的解决方案,如现场传感器和生产管理系统,依靠技术来监测和管理与能源有关的参数。

- 运行管理可视化

- 生产管理可视化

- 现场数据的可视化

2、降低炉膛/锅炉烟气中过量氧含量

当烟气中存在过量氧(O2)时,结果是不完全燃烧。通常,O2保持在更好水平的1.5-2%之内,但是已经证明激光传感技术可以提高CO/O2/CO2测量的速度和可靠性,并且进一步减少过量的O2,从而更加节省能量。

使能技术

横河的新型TDLS8000把所有业界的特性融合在一台强大的设备中。其平台设计适用于现场测量,无需进行样品抽取和样品处理。利用非接触式传感器,TDLS8000可以在腐蚀性、刺激性、高粉尘浓度等多种严酷的工艺类型中进行测量。

客户面临的挑战

油品调合是将原油转化为汽油等成品的一步。当使用传统的混合技术如油箱混合和比例混合时,精炼者倾向于使用过量的添加剂以保证汽油产品符合调节器设定的规格。然而,由于混合添加剂的成本很高,需要既能降低成本又能满足规格的混合溶液。

我们的解决方案

横河提供了一个混合优化系统,或称混合特性控制(BPC)解决方案,它根据NIR分析仪连续在线分析产品特性所测得的值,实时计算混合比,自动修改控制器的设定值来自动调节在线混合比。

除了BPC解决方案之外,横河还可以提供集成的非现场解决方案,这些解决方案覆盖所有非现场工艺操作,例如石油移动系统(OMS)、实验室信息系统、分析仪系统和调度/计划系统。

客户获得的收益

以下是客户反馈的通过使用横河的BPC和其他非现场解决方案可实现的收益:

- 提高安全性:通过系统引导和监督非现场操作的安全性。

- 提高产品质量:系统监督可尽量减少可能导致产品污染的操作错误概率。

- 改善环境性能:OMS的运动控制解决了可能由油箱溢出和其他因素引起的环境问题。

- 提高操作效率:通过阀门机动化以及搜索现有隔离物来搜索排好队列的作业,大幅减少每个人执行的操作数量。

- 扩展空间感知:所有操作员都可以获得完整的区域感知,并且系统数据库保持不断更新。

详细介绍

横河在炼油行业有大约1000个项目的经验,从炼油商那里赢得了较高的信誉。

设计与工程

前期工程与设计(FEED),主要仪器供应商(MIV)服务。

安装和调试

现场工程、集成测试、交钥匙服务。

操作与优化

优化咨询,24/7操作支持,在线诊断支持。

维护与升级

资产优化、在线升级、生命周期解决方案支持。

改造扩建

在线扩展,热转换。

参考

- CENTUM CS 3000 plays key role in Malaysian waste oil to diesel project.

- Yokogawa proposed to provide its systems and services as the main instrument vendor.

- To replace the existing CENTUM XL control station with the latest Yokogawa CS 3000 hardware and upgrade the control network.

- The plan was to minimize plant downtime by doing a hot cutover from the old to the new control system.

- Smooth and safe switchover to the new system

- Easy-to-use, easy-to-engineer system, plus various post-installation enhancements

- Tuned controllers for smooth plant operation and better traceability of process upsets

- Various other improvements thanks to advanced process control and MVC implementation

- Exapilot was introduced to maximize operational efficiency at an experimental refining facility.

- To prevent operator errors, it was essential to standardize operating procedures.

- Computerized Maintenance Management System by PRM and SAP Schedules Field Instrumentation Maintenance.

- The frame applications and DTMs support the preventive maintenance strategy with self-diagnostic and condition monitoring.

PetroChina Guangxi Petrochemical Company has completed construction of a combined refinery and petrochemical production complex in Qinzhou, a port city in China's Guangxi Autonomous Region. With a 10 million ton per year capacity, the refinery is one of China's largest, and is truly world class, using a highly advanced hydrogenation process, with the main process technologies coming from the USA and France.

- To decrease downtime and maintenance costs, the decision was made to introduce Yokogawa's CENTUM DCS.

- With well-experienced MAC approach, Yokogawa replaced successfully legacy DCS.

马图拉炼油厂具有重要战略意义,负责向印度西北部的客户供应柴油、汽油、航空涡轮机燃料、煤油、液化石油气、燃料油和沥青。

- Successful migration of in-line blending distributed control and oil movement systems.

- To minimize operator intervention and to keep the product properties on specification.

- Smooth project execution with no schedule and/minimal safety incidents.

- Easy to use, easy to reconfigure interface that has resulted in numerous post-installation enhancements.

- Minimizing day-to-day plant operation problems including reducing the alarming factor.

- The project goals emphasized schedule, quality, cost and safety.

- More than 40 sub-system interface cards are utilized for b14 partners company7s system integrated with CENTUM CS 3000.

- Integrated CENTUM VP and ProSafe-RS Systems Ensure Nonstop Operation of ADU/DKU Processes.

- "This is a real VigilantPlant! We will continue to improve our production efficiency."

- Exapilot contributes to safety, reduces cost, and retains operational know-how.

- CENTUM CS 3000系统会根据所获取的过程数据计算出多项关键性能指标并对其进行分析,以提高综合石化厂的生产效率

- 在工厂启动阶段,PRM帮助用户完成了回路的检查工作。

- The AR1 refinery recently replaced its legacy DCS with Yokogawa's CENTUM CS 3000.

- Achieving an Intelligent Oil Management System.

- HMEL selected an integrated solution from Yokogawa

- Yokogawa India oversaw and implemented the engineering, installation, and commissioning of the refinery

Operators must receive diagnostic information before a line block leads to a malfunction. Yokogawa provides predictive diagnostics based on trend analysis of the blocking factor, which improves maintenance efficiency and reduces maintenance costs.

Recently, air pollution legislations such as the Clean Air Act to reduce the amount of air pollution are increasing worldwide. The Clean Air Act address numerous air quality problems. One of these problems is acid rain caused by sulfur dioxide and nitrogen oxide emissions from fossil-fueled power plants and other industrial and transportation sources.

The oil refining industry today faces increasingly strict regulations that dictate both the quality of its products and the diligence of its production processes. As the pioneer of the vortex flow meter technology, Yokogawa's challenge in bringing innovative flow measurement solutions to users in various process industries continues to this day.

The top gas generated at the top of a distillation column in a petroleum refinery's fluid catalytic cracker (FCC) is used to produce gasoline and LPG. The GD402 Gas Density Meter features an intrinsically safe and explosion-proof design, fast response, and a dust-proof, anti-corrosive, and flame-proof construction.

O2 measurement in hydrocarbon vapor is used for safety monitoring in vacuum distillation columns in petroleum refining. With conventional paramagnetic oxygen analyzers, O2 concentrations are obtained through an extractive sampling system, which conditions the sample prior to being analyzed.

In limestone-gypsum flue gas desulfurization systems, the consumption of a desulfurization agent (lime) is controlled using online pH analyzers.

Reverse osmosis (RO) is a separation process that uses pressure to force a solution through a membrane that retains the solute on one side and allows the pure solvent to pass to the other side. More formally, it is the process of forcing a solvent from a region of high solute concentration through a membrane to a region of low solute concentration by applying a pressure in excess of the osmotic pressure.

Fired heaters are used for various processes in oil refining and petrochemical plants.

Storage tanks are used in a variety of industries ranging from holding crude oil to holding feedstock for vinyl chloride monomer (VCM).

Delayed Coker is a type of coker who's process consists of heating residual oil feed to its thermal cracking temperature in a furnace. The most important variable in industrial furnace control is temperature. Temperature is measured throughout the furnace in different zones and temperature effects the materials being manufactured and therefore must be precisely monitored to prevent deviations in quality of the final product.

Challenges

- The distance is not so long, but there are many pipes and tanks ("Pipe Jungle") in the field.

- Had to avoid the obstacles and take care multi path condition.

Solution

Repeater is installed on high place between control room and monitor position. The extend cable is used for antenna of Gateway.

- Temperature Transmitter (YTA) x1, Pressure Transmitter (EJX) x2

- Fast online gas chromatograph (GC) analysis for LPG distillation.

- The analytical upgrade project with Yokogawa's process GCs was complete success.

Industrial Combustion sources such as thermal cracking furnaces and, process heaters play a critical role in the process industry.

The ammonia (NH3) gas is injected to remove the NOx and thus reduce the NOx concentration in the stack flue gas. With conventional NH3 analyzers that perform measurements indirectly, NH3 concentrations are obtained through a sampling system. Therefore, there are problems with the maintenance and running costs of the sampling system, and time delays in measurement. The TDLS8000 Laser Analyzer is the solution to all these problems.

A multivariable model based predictive control (MPC) was implemented at the FCCU "A" in YPF S.A. Refinería La Plata.

There are three MPC controllers installed: one covering the reactor-regenerator-main fractionator, other controlling the gas con- centration plant ant the third controlling an isolated depropanizer column. The paper describes the implementation of the project, the controller structure and the main results obtained from the MPC.

Visual MESA© is a steam system optimization and management computer program that was originally developed at Chevron and now marketed by Nelson & Roseme, Inc. Visual MESA is currently used at refinery and chemical manufacturing sites to optimize the overall site steam system and the parts of the electrical system that economically trade off with the steam system.

This paper will explore significant optimization variables and constraints commonly encountered in refinery steam system optimization, the strategies Visual MESA uses to deal with them.

Hydrogen management can have a significant effect on refinery utility supply through the integration with the rest of the utilities. Real-time optimization of hydrogen production in conjunction with steam, power and fuels can yield significant savings opportunities for the refinery.

This paper describes the tasks performed to develop and implement real time, online models, to help with the three KNPC refineries energy cost minimization and energy management, which are scheduled to perform it automatically. They allow to clearly identify the different economic trade-offs that challenges the operation of the site wide energy systems at minimum cost while reducing the energy waste and, therefore, CO2 footprint. Recommendations given by the optimizers are taken into account by operations on a daily basis

In general, refineries exhibit a very good potential for real time monitoring and optimization using Visual MESA Energy Management System.

Based on our extensive experience, overall benefit in the range of 2% to 5% of the total energy cost can be achieved. Expected project payback is always less than one year.

This article describes the tasks performed to develop and implement a real time, online model for energy cost minimisation and energy management at KNPC's MAA refinery.

After a description of the main project implementation tasks, the Real Time Energy Management System's (RTEMS) functionalities are described and the optimisation implementation procedures are commented on. Finally, several obtained results are presented.

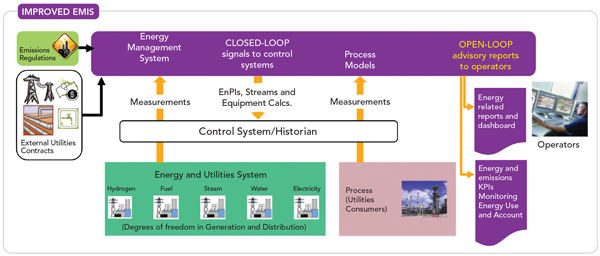

Utilities and energy systems are often the major source of SOx, NOx and CO2 emissions, therefore, emissions control and the management of credits and quotas are tightly interrelated with energy management.

In the case of refineries, chemical and petrochemical plants, energy represents the main cost (second to feedstock) and therefore its reduction has become a bottom line business decision. The energy systems at these sites are inherently complex, with the emissions cost analysis and limits compliance introducing an additional factor to the complexity of the energy costs reduction challenge.

Process plants use different type of fuels, they often operate cogeneration units, their steam networks consist of several pressure levels, there are different types of energy consumers and there are emission limits to be observed. Import or export of electricity in deregulated markets, which could also be traded off with more or less CO2 and other contaminant gaseous emissions, increase the optimization problem complexity.

The Repsol YPF Tarragona Refinery operates a large, complex steam system. Utilities Optimization has been performed with an on-line computer based steam management program (VISUAL MESA) in order to make the Refinery more energy efficient and reduce steam system operating costs.

VISUAL MESA allows operators and engineers to:

- Monitor steam production and use;

- Optimize the production and use of steam, fuel and power in order to reduce costs;

- Perform "what-if" studies, and

- Audit the system with continually validated data. Nelson & Roseme, Inc. and Soteica Europe S.L. have worked with Repsol YPF Tarragona

Petronor is Spain's largest refinery, with a processing capacity of eleven million tons a year. Its energy system is large and complex, therefore the auditing and control of energy costs are a real challenge. This paper describes the tasks performed together with Soteica, using a modern on line information and optimization system tools, to reduce energy costs.

This paper will not describe just all the features of the software or fully explain on-line optimization technology. The objective of this work is to present some interesting facts and lessons from the experience of implementing a cost based optimization program at thirty oil refineries and petrochemical complexes, around the world, since 1997. This paper will focus on the key optimization variables and constraints in steam system optimization, how they should be handled and how the human and organizational aspects can be addressed.

A detailed model of the steam, fuels, electricity, boiler feed water and condensates systems has been built, including all the interactions between these systems, real plant constraints and degrees of freedom of their operation. Such a model is scheduled to perform automatic executions of the optimization of the entire system and is continually populated with validated live data from the process. A calculation of equipment efficiencies is done as part of the performance monitoring activity of the model. Other monitoring aspects include the continuous auditing of the energy system so the data can be relied on for evaluating the value of energy production and usage, and waste can be reduced or eliminated.

Industrial facilities where power and steam is produced (i.e., Cogeneration) exhibit a very good potential for real time monitoring and optimization using Visual MESA Energy Management System.

Based on our extensive experience, overall benefit in the range of 2% to 5% of the total energy cost can be achieved. Expected project payback is always less than one year.

Visual MESA was successfully applied to many industrial facilities worldwide, several of them operating steam and power generation networks of different complexity and capacity but all with energy cost savings.

This paper discusses real industrial examples in which the sitewide utilities system of refinery and petrochemical Sites are optimized with a real time, on line, industrially proven software. Experiences gained during more than 20 years of industrial projects deployed worldwide are commented (Refs. 1 to 10 are related to some recent projects). Main project steps are explained and critical details to be taken into account to assure successful use and proper technology transfer are presented. Specific case studies will be discussed in the paper.

This paper describes the tasks performed, together with Soteica, using modern on line information system tools to assist with the energy system management.

After a feasibility study, TOTAL decided to test an on-line model for site wide energy system management. TOTAL operates a large and complex energy system at Feyzin refinery. A detailed model of the energy system has been built and it is continuously fed with validated (not reconciliated), real-time data. It includes all the actual constraints of the site and decision variables for their operation. Continuous performance monitoring is also done, since the model writes back its results to the Real Time Data Base (Plant Information system). It also provides reliable data that helps to audit the energy productions and usages within the site energy system, and in that way wastes can be detected and eliminated.

An online steam management program can help refineries manage their steam and utility systems more energy efficiently and reduce their operating costs through optimisation and monitoring

Big and complex industrial facilities like Refineries and Petrochemicals are becoming increasingly aware that power systems need to be optimally managed because any energy reduction that Operations accomplish in the producing Units could eventually be wasted if the overall power system cost is not properly managed. However, process engineers always attempted to develop some kind of tools, many times spreadsheet based, to improve the way utilities systems were operated. The main drawback of the earlier attempts was the lack of data: engineers spent the whole day at phone or visiting the control rooms to gather information from the Distributed Control System (DCS) data historian, process it at the spreadsheet and produce recommendations that, when ready to be applied, were outdated and not any more applicable.

Utilities and energy systems are often the major source of SOx, NOx and CO2 emissions, therefore, emissions control and the management of credits and quotas are tightly interrelated with energy management. In the case of refineries, chemical and petrochemical plants, energy represents the main cost (second to feedstock) and therefore its reduction has become a bottom line business decision. The energy systems at these sites are inherently complex, with the emissions cost analysis and limits compliance introducing an additional factor to the complexity of the energy costs reduction challenge.

Repsol Cartagena was the first oil refinery to be built on the Iberian Peninsula. It has an annual crude distillation capacity of 5.5 million tonnes, with two main areas of production: fuels; and lube oils, asphalts and paraffinic and aromatic oils. Repsol Cartagena is currently involved in an ambitious expansion project, whereby 22 new units will be built, increasing its refining capacity to an annual 11 million tonnes.

The energy systems, the steps for the implementation of Visual MESA and several features of the model are described in this article, with a focus on the use of the software for the calculation of energy-related KPIs. The EMS implementation project is discussed and the main conclusions relative to the reduction in operating costs are also presented.

This paper shows real industrial examples in which, with the existing equipment, continuous CO2 emissions reductions were achieved while optimizing the energy systems by using an on line model. The importance of including the cost of CO2 emissions and how it should be taken into account when managing energy systems is explained. Furthermore, the optimization model is useful to perform case studies to evaluate energy system modifications taking into account this aspect.

This paper describes the tasks performed together with Soteica, by using an on-line model, to help achieve site wide energy costs minimization. A detailed model of steam, fuels, electric, boiler feed water and condensates system has been built, contemplating all the real constraints and degrees of freedom for their operation. The electric power system is also modelled as it interacts with the steam production and usage. Such a model is continually validated with live data. A continuous calculation of equipment efficiencies is done as part of the performance monitoring activity of the model that is running as a service.

A refinery energy system is modelled, including all the constraints, with continuous model validation using live data. Performance monitoring includes the tracking of equipment efficiencies by utilising validated data for its continuous calculation,

Experiences gained during more than 20 years of industrial projects deployed worldwide are commented. Main project steps are explained and critical details to be taken into account to assure successful use and proper technology transfer are presented. Specific case studies will be discussed in the paper. Open loop vs Closed loop implementation is also presented.

Rohm and Haas Company is one of the world's largest manufacturers of specialty materials, including adhesives, sealants, coatings, monomers, electronic materials, inorganic and specialty solutions, and ion exchange resins. Founded in 1909 by two German entrepreneurs, Rohm and Haas has grown to approximately $6 billion in annual revenues.

Alarm management is not just a project that has a start and end date; it's a continuous cycle. Once the alarm system has been reviewed and improvements have been identified, we must check that controls are in place to ensure the alarm system remains functional. The key is to ensure that the system is continuously monitored and any changes are fully documented. There are seven key steps for alarm management. Rationalization is one of those critical steps.

This paper shows how to improve distillation operations by focusing on procedure automation. It will review the importance of using procedures in distillation operations and highlights the collaboration work underway between Fractionation Research Inc. (FRI) and Yokogawa Corporation to improve procedural operations.

The worlds of process automation and production management have been converging for some time. What once used to be islands of automation and production management functionality connected through highly proprietary integration schemes that were costly to maintain have developed into integrated platforms that provide seamless data exchange between the world of automation and the plant floor, the functions of production and operations management, and integration with business level systems.

The world of process automation is governed by procedures. While we like to refer to the process industries as being largely "continuous", this could not be further from the truth. Process manufacturing is constantly in flux.

From engineering to installation, commissioning, operations, and maintenance, FOUNDATION fieldbus offer significant cost reductions of 30 percent or more versus conventional analog systems. Many of these cost reductions come from the advanced functions that fieldbus offers versus analog technology.

The automation suppliers that will be successful in the long term will be those that effectively address application or industry specific problems for end users with a value proposition that cannot be ignored. These problems exist throughout the process industries today, and they won't be solved by simply offering a product, but through a combination of hardware, software, services, application expertise, and knowledge.

In ARC's view, customers need a compelling business value proposition to justify investment in any kind of automation. Vigilance and VigilantPlant were created with this in mind. Yokogawa's vision with VigilantPlant is to create an environment where plant personnel and operators are well informed, alert, and ready to take action.

Yokogawa has come a long way in making its message clear to the world of process automation. Last year, the company embarked on a full-scale global marketing campaign to make customers aware of the company's focus on system reliability, security, dependability, and robustness. Dubbed "Vigilance", the campaign created a unified message for the company and greatly helped expand awareness of the Yokogawa brand and corporate philosophy.

Process automation end users are under more pressure than ever to do more with less. The current economic climate means that many automation capital projects are on hold. With capital budgets tighter than ever, users instead focus on operational budgets (where cost cutting is also a key concern), or on automation investments with a very rapid return on investment.

In today's dynamic industrial marketplace, the only constant is change. Raw material costs, energy costs, market demands, environmental and safety regulations, technology, and even the nature of the labor force itself are constantly changing, and not always in predictable directions.

High volumes of volatile organic compounds (VOCs), typified by trichloroethylene and tetrachloroethylene, have long been used in various industrial fields for their high degrees of industrial usefulness. On the other hand, there is a growing awareness of environment preservation today, and of the fact that we face serious environmental pollution due to such harmful VOCs.

With fired heaters, users hope to get greater efficiency and reduced emissions but often are disappointed. Given the number of fired heaters operating every day and their importance in the process industries, any improvements realized across the board will have huge impacts. More units can reach their potential with some simple changes in work practices and technology upgrades.

Migration of a refinery's DCS provided an opportunity to reconfigure and consolidate the control rooms and operational management system.

July 2011

Process plants are run according to operational procedures. These procedures consist of a set of tasks that are executed in a consistent manner to achieve a specific objective, such as starting up, shutting down or transitioning a unit as part of making a product.

April/May 2007

A Yokogawa ProSafe-RS safety instrumented system (SIS) will be the nucleus of a new fire and gas safety system at Shell's Clyde (NSW) refinery. The contract includes the control system, system engineering and installation and supervision.

Process automation in oil refineries is undergoing major changes, driven by customers frustrated by what they consider to be slow and incremental advances from the main automation original equipment manufacturers (OEMs) in the industry. ExxonMobil has become a de facto industry representative and is driving vendors like Yokogawa and others to reevaluate how large-scale automation projects are implemented.

Using wireless technology for monitoring a variety of measuring points in Industrial Plants has becoming a very attractive choice for plant managers. Today, the plant manager is able to build a quick and cost effective network solution to enable flexible information acquisition and to improve maintenance efficiency and safety.

Visual MESA Systems empower improved operational efficiencies in real time

Machines don't panic and they always do what they're told. But they can't think on their feet and can't react to situations for which they have not been programmed. Which do you want to depend on when your life depends on it?

CONTROL, January 2013

Standard Automation Methodology Improves Operations and Prevents Incidents by Enabling the Sharing of Best Practices Among Operators.

ARC believes that by implementing procedural automation, many process plants can minimize variability to help ensure smooth, efficient, and safe state transitions.

The global refining industry is constantly evolving and responding to new crude supplies and sources, more stringent fuel/product specifications, perpetually changing demand patterns and other global and regional trends. Increased competition from large, efficient refineries is forcing small- to mid-sized refiners to rethink their strategies to remain competitive.

Increasing oil prices are reducing the relative feedstock and energy costs advantages refiners and petrochemicals producers have recently enjoyed. Allied with the high cost and growing scarcity of skilled staff, a fundamental shift in mindset towards plant operations and maintenance is required to assure organizational resilience. Therefore, the desire to achieve enhanced cost structures through innovation in operating models and digitalization has intensified.

Wiring temperature sensors installed in a chimney back to a control room can be challenging and expensive, so many plants and facilities are instead implementing wireless solutions, such as this Yokogawa YTMX580 8-input temperature transmitter.

Adding process considerations improves energy savings and production performance.

下载

视频

The YSS1000 setting software (hereinafter referred to as the YSS1000) is package software to configure the functions of the YS1000 series (hereinafter referred to as the YS1000) devices. Writing and reading of parameters and user programs of the YS1000, and PID tuning and monitoring of user programs can be performed through the use of communication.

How much do you know about pressure transmitters? Are you accurately, quickly and reliably measuring pressure? Ultimately, the drive of any good pressure transmitter is to get an accurate, reliable pressure measurement to the data user quickly. This video gives you the answers to your basic questions about pressure and pressure transmitters.

想要了解更多的信息,技术&解决方案?

联系我们