Tokyo, Japan - November 13, 2019

Yokogawa Electric Corporation (TOKYO: 6841) announces the November 14 release of Plant Resource Manager (PRM™) R4.03, the latest version of a software package in the OpreX™ Asset Management and Integrity family that facilitates the monitoring and control of plant operations by centralizing the management of large volumes of data from instrumentation and manufacturing equipment. PRM R4.03 features powerful device diagnostic functions that help to optimize plant maintenance and ensure safe operations. This translates into greater efficiency and accelerates the transition from reactive to predictive maintenance.

Development Background

Manufacturers are constantly looking for ways to improve maintenance efficiency by using software tools like PRM that can centrally manage large amounts of maintenance information and other types of data from plant monitoring and control devices as well as manufacturing equipment, thus enabling the quick identification of device failures that could interfere with the safe operation of plants. To meet such needs, Yokogawa has continued to enhance PRM's functions.

In recent years, plants have become increasingly reliant on digital communications to handle an ever growing amount of data. As a result, operators enjoy improved access to field device maintenance information and information on process parameters. In response to customer needs for greater maintenance efficiency and reduced risk of device failure, Yokogawa has enhanced PRM's device and equipment diagnostic functions to make more effective use of data from digital devices that is needed to adjust their operating conditions. Also, to streamline and accelerate plant start-up operations, a function that helps to set device parameters has been added.

Enhancements

- Reduction of maintenance workload

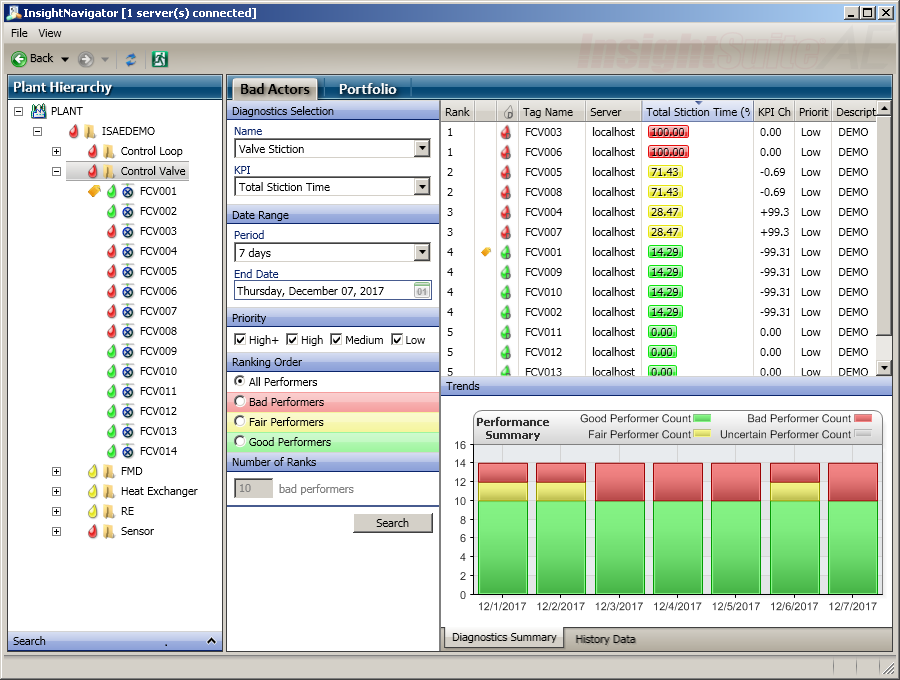

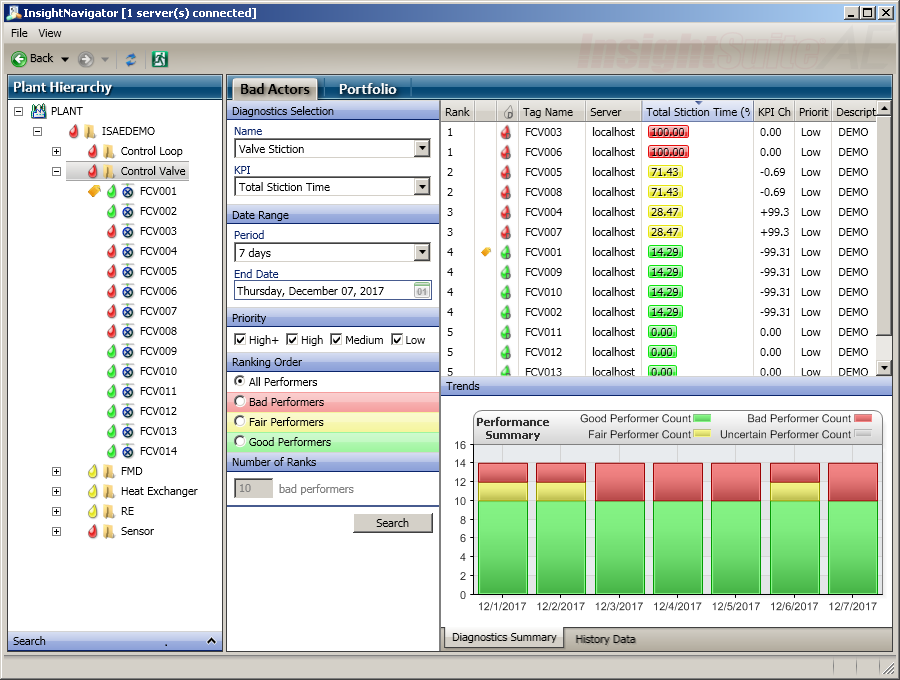

The starter edition of InsightSuiteAE, a Yokogawa software tool for the viewing of diagnostic data that can aid in the identification of device degradation, is now included with PRM. This allows PRM to identify devices that are rarely used and thus may have deteriorated less and have a low risk of failure. Such proactive condition-based monitoring reduces the daily workload for maintenance personnel because only selective device checks need to be carried out.

Diagnostic data screen for InsightSuiteAE starter edition

Zoom - Reduced risk of equipment failures

PRM now comes with an interface package for generic systems that enables this software to connect with device and equipment diagnostic systems. This helps to identify abnormal conditions in peripheral equipment and field devices. For example, by connecting to Yokogawa's cavitation* detection system, PRM can identify cavitation inside pumps in real time. By using PRM's alarm function, operators can receive immediate notification of abnormal conditions so that evasive actions such as limiting the flow rate can be taken to prevent pump failure. - Faster plant start-ups

A device parameter audit function has been added to PRM that enables parameter checking to be performed immediately at plant start-up. This confirms that the correct parameters have been set for all field devices of the same model. This function also makes it easier to troubleshoot problems by checking parameter changes and logs.

About PRM

The PRM software centrally manages large amounts of status and maintenance information from automation assets as well as production assets. PRM supports the FOUNDATION™ fieldbus, HART®, ISA100 Wireless™, and PROFIBUS field digital communication protocols. PRM has various maintenance support functions, including online functions for monitoring and diagnosing devices and equipment. PRM can work with the FieldMate™ device management software for setting, adjusting, and managing field devices. Through FieldMate, the current device information stored in PRM can be checked in the field. For improved access to maintenance information, the PRM device information can also be accessed from any human interface station (HIS) linked to the CENTUM™ VP integrated production control system.

About OpreX

OpreX is the comprehensive brand for Yokogawa's industrial automation (IA) and control business. The OpreX name stands for excellence in the technologies and solutions that Yokogawa cultivates through the co-creation of value with its customers, and encompasses the entire range of Yokogawa's IA products, services, and solutions. This brand comprises the following five categories: OpreX Transformation, OpreX Control, OpreX Measurement, OpreX Execution, and OpreX Lifecycle. PRM, an OpreX Asset Management and Integrity family solution in the OpreX Transformation category, delivers operational excellence throughout an enterprise's activities, from production through to supply chain optimization and risk and business management. With this brand, Yokogawa will deliver integrated solutions that address specific needs and support its customers in their efforts to transform and grow their businesses.

* A physical phenomenon whereby the differential pressure of a liquid in a pump or some other kind of plant equipment causes bubbles to rapidly form and then burst. The shock produced by the bursting of the bubbles damages the equipment.

Major Target Markets

Industries such as oil and gas, petrochemicals, chemicals, iron and steel, pulp and paper, electric power, and wastewater treatment

Applications

Field device maintenance and start up, plant operation support

About Yokogawa

Founded in 1915, Yokogawa engages in broad-ranging activities in the areas of measurement, control, and information. The industrial automation business provides vital products, services, and solutions to a diverse range of process industries including oil, chemicals, natural gas, power, iron and steel, and pulp and paper. With the life innovation business, the company aims to radically improve productivity across the pharmaceutical and food industry value chains. The test & measurement, aviation, and other businesses continue to provide essential instruments and equipment with industry-leading precision and reliability. Yokogawa co-innovates with its customers through a global network of 113 companies spanning 60 countries, generating US$3.6 billion in sales in FY2018. For more information, please visit www.yokogawa.com.

The names of corporations, organizations, products, services and logos herein are either registered trademarks or trademarks of Yokogawa Electric Corporation or their respective holders.

Related Products & Solutions

-

Plant Resource Manager (PRM)

- Plant manager software

- Properly manage facility for highly reliable, stable plant operation

- PRM contributes to quality of maintenance plans and optimizing maintenance costs throughout plant life cycle