The EJXC40A Digital Remote Sensor (DRS) transmitter connects two pressure sensors, the primary sensor (for high-pressure side) and secondary sensor (for low-pressure side) with DRS dedicated communication cable to measure differential pressure. The DP is transmitted via a 4 to 20 mA analog signal. EJXC40A is suitable to measure liquid, gas, or steam flow as well as liquid level, density and pressure.

Key Features

- High performance, high accuracy and high reliability

Better performance over long capillaries of diaphragm seal system. - Suitable for level measurement of a tall tank

DRS cable length (maximum): 45 m - Signal characterization for various tank types

- Exida SIL 2 / SIL3 Certified

About OpreX

OpreX is the comprehensive brand for Yokogawa’s industrial automation (IA) and control business and stands for excellence in the related technology and solutions. It consists of categories and families under each category. This product belongs to the OpreX Field Instruments family that is aligned under the OpreX Measurement category.

Details

Plants run better with Yokogawa Digital Remote Sensors.

At it's heart, Yokogawa's Digital Remote Sensors with DPharp digital sensor technology offer the performance and device intelligence needed to get greater insight into your process.

Digital Performance

Yokogawa's DPharp digital sensor offers twice the performance and stability of the competitor's analog sensors. The DPharp uses the latest in IC Chip-style design and manufacturing technology. Analog sensors are based on older design technology. Although analog sensors are good, the modern DPharp sensor outperforms them. A Yokogawa transmitter with DPharp digital sensor will give you the consistent, reliable, accurate measurement you need.

Poor Performance = Lost Money

More Information

Yokogawa's DRS Pressure System offers greater insight into your process. One DRS can supply differential pressure (primary variable), high-side pressure, high-side sensor temperature, low-side pressure, and low-side temperature.

More Information = Found Money

Signal Characterization

Signal characterization is a versatile function available on all Yokogawa pressure transmitters. The function is used to compensate the analog 4 to 20 mA output signal for non-linear applications. Such applications include tank strapping or flow measurements; but, it can be used in any application where the relationship between the pressure input and the desired output signal are known. This feature can use up to 31-points.

Greater Flexibility = Found Money

Local Indicator

All of the process variable's measured by Yokogawa's transmitter can be displayed on the easy to read local indicator. The indicator can display any of the variables measured (DP, SP, Capsule temperature); alarm codes with short text; and a sweeping bar graph to give a graphical representation of the process. Fully programmable, the indicator is customizable for your needs. Unlike competitor's transmitters, the indicator is not driven off the 4 to 20 mA analog signal, but, exist on a separate circuit. This allow the display to operate independently from the output signal, so it can indicate information that maybe more useful at the transmitter location.

More information = Found Money

Rugged Construction

A ruggedly constructed pressure transmitter can reduce failures. Yokogawa's pressure transmitters have construction features allowing them to outlive your plant.

Note: All construction materials conform to NACE material recommendations per MR0175 / ISO15156.

Ruggedness = Reliability

Independent Verification

The Yokogawa pressure transmitter series' performance and reliability has been verified by independent third parties from around the world.

Functional Safety

All Yokogawa pressure transmitters are designed and certified to IEC61508:2010 Parts 1 through 7 and IEC61511:2004 Parts 1 through 3. They are certified for single transmitter use in SIL 2 safety applications and dual transmitter use in SIL 3 safety applications with no special option required. With Yokogawa's transmitters, no longer will you have to maintain two seperate inventories - one for production applications and one for safety applications.

Functional Safety = Reliability

Active Sensor Technology

The DPharp sensor is an active sensor. This means that the sensor is constantly supplying a signal even when the process has not changed. If the signal is lost from the sensor, the transmitter knows there is an issue. Competitor's analog sensors are passive. They do not supply a continual signal, so is the sensor still working when there is no signal? An active sensor is inherently safe.

Inherently Safe = Reliability

Patented Self-check System

Yokogawa's pressure transmitters as a patented real-time reverse check of the signal to ensure all calculations are preformed correctly. This system ensures that the transmitter is converting the signal from the sensor into the analog signal and digital protocol correctly.

Inherently Safe = Reliability

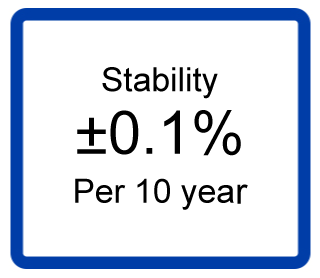

Yokogawa's DPharp pressure transmitters offer long-term stability and diagnostics to make your maintenance routine easy.

Extended Calibration Intervals

Yokogawa's pressure transmitters have a long-term stability under all operational conditions. As you gain experience with these transmitters, you will be able to extend the time between calibration checks.

Quicker Maintenance = Less Downtime

Multiple Communication Options

Yokogawa offers several platforms to communicate to your transmitter.

FieldMate is a PC based communication platform that can communicate with your transmitter and manage your entire instrument inventory.

FieldMate HHC is a traditional hand-held platform that allows you to take that information into the field.

Forgot your HHC? No problem. The LPS feature on the transmitter allows you to update 9 parameters without the use of an HHC.

Quicker Maintenance = Less Downtime

Simple Troubleshooting

When your transmitter is 'alarming', you do not have the time to look for the manuals and go through them trying to figure out what is wrong; you need to get the transmitter up and operating again as quick as possible. Yokogawa's pressure transmitters have a simple description of the error code available on the local display. This simple description may help you correct the problem and get back to making product quickly. If you need more help, the manual does have a full description of all codes and suggest corrective actions.

Quicker Maintenance = Less Downtime

Tall Tanks

Tall tanks that have process connection that are 50 feet or more apart can have a great deal of temperature effect when using traditional oil-filled capillary systems. The use of a DRS can minimize this effect by replacing the capillaries with electronic signal wiring.

Differential Temperature

Tank farms cast shadows that can leave one process connection in direct sun light and the other process connection in shade. This results in a differential temperature between the connections. This can cause errors in the differential measurement between the two connections. The DRS compensates locally for ambient temperature, reducing this error, so it’s not influenced by solar radiation and temperature change.

Extreme Low Ambient Temperature

Tank farms located outside can be exposed to extremely cold ambient temperatures. Measuring tank level in this environment using a differential pressure transmitter with oil-filled capillaries may require expensive heat tracing to keep the oil from freezing. Adding heat tracing gives the maintenance group another system to maintain. The DRS eliminates the need for heat tracing by replacing the oil-filled capillaries with electronic signal wiring.

Differential Pressure (DP)

The transmitter outputs differential pressure, using the two transmitters of same model and capsule for primary (high-pressure side) and secondary (low-pressure side) pressure sensors.

- When using EJX530A Gauge Pressure Transmitter

| Capsule | Measurement Span | Range |

|---|---|---|

| A | 2 to 200 kPa | −200 to 200 kPa |

| B | 0.01 to 2 MPa | −2 to 2 MPa |

| C | 0.05 to 10 MPa | −10 to 10 MPa |

| D | 0.35 to 50 MPa | −50 to 50 MPa |

- When using EJX630A Gauge Pressure Transmitter

| Capsule | Measurement Span | Range |

|---|---|---|

| A | 2 to 200 kPa | −200 to 200 kPa |

| B | 0.01 to 2 MPa | −2 to 2 MPa |

| C | 0.05 to 10 MPa | −10 to 10 MPa |

| D | 0.35 to 70 MPa | −70 to 70 MPa |

Valve Manifolds

Yokogawa offers a range of valve manifolds and accessories for combination with the DPharp EJX and EJA series transmitters in partnership with AS Schneider-Germany and WIKA/Micro precision-India.

Communicators

Yokogawa manufactures a communicator for your needs. Yokogawa communicators are available for BRAIN Protocol, HART Protocol, FOUNDATION Fieldbus, PROFIBUS PA, ISA100, or Modbus. All out communicators are compatible with Yokogawa products as well as other products on the market.

Communication Convertors

Yokogawa offers communication converters to convert secondary HART protocol variables to a 4 to 20 mA analog signal or all the HART variables to MODBUS RTU.

Important Notice

| Date | Remarks |

|---|---|

| 2024/12 | Important Notice for Safe Use of Products |

Resources

DP Level transmitter configuration can be very time consuming. Yokogawa DPharp EJA/EJX Pressure transmitters realize reduction in man hours by smart level setup feature.

Yokogawa DPharp EJA/EJX Pressure transmitters do not need frequent re-zeroing due to superior long term stability, it contributes to reduce maintenance time.

Differential pressure level measurement has an enemy- temperature. Temperature can have a negative effect on the accuracy of level measurement. This article covers why temperature has this effect and how it can be reduced.

Downloads

Instruction Manuals

- EJXC40A Digital Remote Sensor (10.3 MB)

General Specifications

- EJX, EJA-E Series Diaphragm Seal System (7.4 MB)

- EJXC40A Digital Remote Sensor (1.7 MB)

Certificates

- EJXC40A Exida SIL Certificate (263 KB)

Drawings

- EJXC40A Digital Remote Sensor Primary Transmitter (EJX530A/EJX630A Output Signal Code -P) (257 KB)

- EJXC40A Digital Remote Sensor Secondary Transmitter (EJX530A/EJX630A Output Signal Code -S) (252 KB)

- C20FW Direct Mount Flanged Diaphragm Seal (Flush type) (353 KB)

- C20FE Direct Mount Flanged Diaphragm Seal (Extended type) (352 KB)

- C30SW Direct Mount Hygienic Diaphragm Seal (Flush Type) (237 KB)

- C30SE Direct Mount Hygienic Diaphragm Seal (Extended Type) (255 KB)

- C10FR Flushing Connection Ring (231 KB)

Looking for more information on our people, technology and solutions?

Contact Us