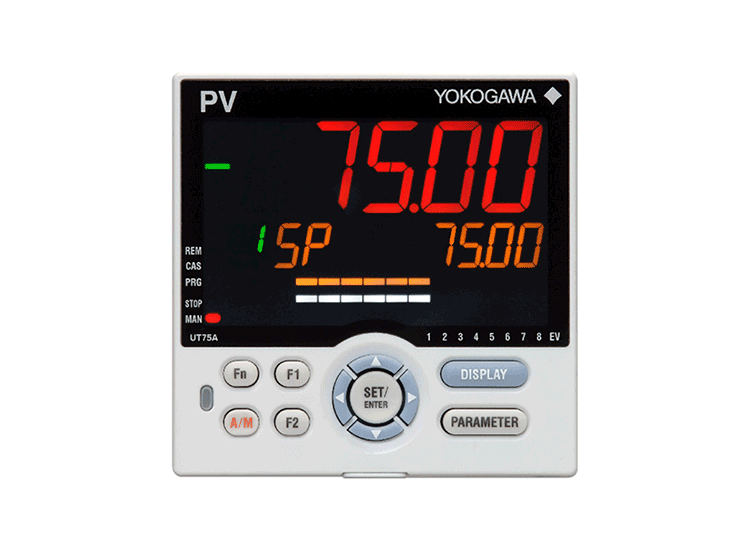

The UT75A temperature controllers employ an easy-to-read, 14-segment large color LCD display, along with navigation keys, thus greatly increasing the monitoring and operating capabilities. A ladder sequence function is included as standard. The short depth of the controller helps save instrument panel space. The UT75A also support open networks such as Ethernet communication.

UT75A Temperature Controller Features

- Comes with a 2-loop control function

- Ladder sequence capacity up to 1,000 steps

- Includes custom ladder function

- Offers 20 sets of target setpoints

- Supports open networks (CC-Link, PROFIBUS-DP, DeviceNet)

Details

Product Details

UT75A Temperature Controller

The Enhanced Peformance, Usability, and Flexibility Meet the Advanced Control Needs in a Wide Variety of Applications

Enhancing Productivity by Managing a Variety of Recipes

Switching between 20 Recipes

- Increasing yield by managing a variety of recipes

- Increasing quality in combination with 16 PID values

Program pattern operation

- Program pattern consists of up to 20 segments

- 2-loop program pattern can be operated

Easy to switch between recipes with a PLC

- Since CC-Link, Profibus, and DeviceNet are supported, it is easy to link to a PLC that manages recipes

Reducing Engineering Costs and Peripheral Devices

Simplifying ladder programs

- Multi-line ladder programs such as numerical calculation can be turned into a single line using a custom ladder instruction.

- This simplifies the ladder programs and facilitates easy engineering and maintenance.

- Created custom ladder instructions can be saved in a file.

- Custom ladder instructions saved in a file can be used by another UT75A temperature controller.

External calculators and sequence control circuits (relay, timer, etc.) can be reduced

- Complex I/O offset calculation and alarm sequence control can be accomplished using a ladder program

- Engineering costs such as wiring and initial setup can be reduced significantly

- A sequence over 2 loops can be created for 2-loop control

Communication with a PLC is possible without using any program

- CC-Link, Profibus, and DeviceNet are supported (optional)

- Since communication with the PLC without using any program is possible, engineering costs can reduced.

Protecting Knowledge of Users

Protecting Knowledge of Users

Custom arithmetic expressions can be created using a ladder program

- Multi-line ladder programs such as numerical calculation can be simplified into a single line using a custom ladder program

- Custom ladder programs are securely managed using passwords

- Custom arithmetic expressions can be made inaccessible to protect the knowledge of users

Inheriting and Enhancing the UT750

2-loop control with a single controller

- 2-loop synchronous and independent operation is available

- The start and stop instructions can be run synchronously or independently. - Program pattern operation and constant value operation are available for 2-loop control

- A sequence can be run by combining the program pattern operation and fixed-point operation.

A variety of arithmetic instructions and large capacity ladder programs

- 15 basic instructions and 111 application instructions

- Ladder program capacity up to 1,000 steps

Advanced arithmetic instructions are available

- Square root, exponential, and logarithmic calculations are available

- Temperature/humidity and CP calculations are available

Reducing Downtime

Universal input and output

- A single backup controller can be used for different control objects with different types of sensors and heaters/actuators

- The UT75A can flexibly respond to a failure and sudden specification changes.

Simple parameter setting and transition using an LL50A

- Parameters can be set on other controllers just by copying them

- Parameters can be set before mounting the controller to the panel

- Parameters can be set without power supply for the controller

Advanced Control

9 Built-in Control Modes

The control mode allows easily configuring settings and making changes with parameters.

- Single-loop control

- Cascade primary-loop control

- Cascade secondary-loop control

- Cascade control

- Loop control for backup

- Loop control with PV switching

- Loop control with PV auto-selector

- Control with PV-hold function

- Dual-loop control

8 Built-in Control Types

PID control

PID control- ON/OFF control (1 point of hysteresis)

- ON/OFF control (2 points of hysteresis)

- Two-position, two-level control

- Heating/cooling control

- Sample PI control

- Batch PID control

- Feedforward control

For the correspondence between the above control mode and control types for each model, please refer to the specifications of each model.

Ladder Sequence Control

With built-in ladder sequence control, the range of applications are dramatically increased. This feature is standard in all the UTAdvanced controllers (except UM33A). The ladder sequence control function can replace a small PLC required by the application. Sequence control and PID control can be performed simultaneously.

- Monitoring and control of external machinery

E.g.: Lamps, switches, timers - Solve digital input/output logic functionality easily.

Number of basic command types: 13

Number of application command types: 73

| [Example of ladder instruction] | [Example of ladder programming] |

|

|

Application Examples of Ladder Sequence Program

Alarm Sequence Control Circuits Can be Reduced

The ladder sequence program is built in the UTAdvanced as standard. The ladder sequence function enables monitoring and controlling peripheral devices such as relays, thus making it possible to reduce costs.

|

[Conventional] |

|

[UTAdvanced] Alarm action is built by the ladder sequence program inside the UTAdvanced, thus making it possible to reduce costs. |

Host System Load is Reduced

|

[Conventional] |

[UTAdvanced] Merit The UTAdvanced with up to 4 analog inputs* enables various types of analog data to be captured directly into the controller and calculated by the ladder program, thus reducing the system-building load of the host. Action: Various types of analog data were captured into the host system (PLC, etc.) and calculated, and the results were processed by the field controller for control via a command. * In the case of the UT55A |

Universal Input/Output

Select Input and Output Types via Configuration

Universal Input

Select from TC, RTD, mV/DC voltage and DC current.

(DC current input: No shunt resistor required)

The input type and range is user selectable via the front panel or by using the LL50A parameter setting software.

The input type and range is user selectable via the front panel or by using the LL50A parameter setting software.

- ±0.1% Indication Accuracy.

- Connect up to two 2-wire transmitters simultaneously.

All instruments have a 15 V Loop Power Supply (15 V LPS) for a transmitter.

In addition, a 24 V LPS is also available simultaneously for some instruments as optional function.

Universal Output

User selectable for relay, Voltage pulse and current outputs.

- Relay output: ON/OFF control, time-proportional PID control

- Voltage pulse output: time-proportional PID control

- Current output: continuous PID control

Heating/cooling control has two sets of universal outputs.

- Any combinations of relay, pulse and current outputs are available.

Drive a motorized control valve by using position-proportional PID.

- The position-proportional PID control function has two sets of relay outputs for direct/reverse rotation of motorized control valve.

- The slide wire input to feed back the valve position is also available.

Auto-tuning (AT) Function

The following conditions can be set in order to increase the accuracy of calculating PID constants using AT .

- Two types of algorithms to calculate PID constants are available for selection.

Normal: fast-rising PID constant

Stable: slow-rising PID constant - High and low output limits can be set individually for control output values during AT runtime.

Fuzzy Logic

SUPER Function Suppresses Overshoot

The field proven SUPER function utilizes a built-in operator experience and fuzzy theory to deliver fine control and suppress overshoot.

SUPER2 Function Suppresses Hunting

The new SUPER2 function utilizes a built-in operator experience and modern control theory to deliver fine control and suppress hunting.

LL50A Parameters Setting Software

Parameter Setting/Program Pattern Creating Function

Parameters that determine controller functions can easily be set: controller model type, controller mode (single-loop control, cascade control, loop control with PV switching, etc.), universal input/output functions, setup parameters and others. It also allows you to create program patterns.

Tuning Function

Used to tune a controller's PID parameters. Displays measured input value, target setpoint, and control output value as a trend graph on a personal computer screen, allowing PID parameter modification, AUTO/MAN switching, control output modification in manual operation, etc.

Ladder Building Functions

Ladder sequence programs can be created and ladder programs can be monitored.

Network Profile Creation Function

Can be used to create an electronic device data sheet for Open Network.

Via Bus Powered USB Cable

Can be set parameters and ladder program while no power supply to controller.

Via Ethernet Communication Connector

Via Dedicated Adapter

Can be used while attached to the control panel.

Can be used while attached to the control panel.

- Applicable Termperature Controllers: UT75A, UT55A/UT52A, UT35A/UT32A, UP55A/UP35A/UP32A, UM33A

Via RS-485 Communication Terminals

Simplicity

Bright & Easy to Read Active Color LCD Display

Versatile Color LCD Display

Optimal Display

The controller menus and layout are adjusted in accordance with the level (EASY, STD, PRO) of information required by the user. If simple temperature or level control is needed, then select the easy configuration. Very sophisticated applications are no problem for the UTAdvanced. Just select the PRO setting and make use of the additional functionality shown in this mode. Advanced applications can be programmed in the PRO setting and then changed back to the easy setting to lock out functions not required by operators.

The controller menus and layout are adjusted in accordance with the level (EASY, STD, PRO) of information required by the user. If simple temperature or level control is needed, then select the easy configuration. Very sophisticated applications are no problem for the UTAdvanced. Just select the PRO setting and make use of the additional functionality shown in this mode. Advanced applications can be programmed in the PRO setting and then changed back to the easy setting to lock out functions not required by operators.

Active Color LCD Display

With Yokogawa's Active color display you can instantly tell, at a glance, the status of your process.

Alarm Status: Active color display changes from white (normal) to red (alarm).

Deviation Status: Color changes based on a PV deviation from SP.

User-defined Color: Choose between white or red display for constant Readings.

Compact Design

The 65-mm depth of the controller reduces the constraints on installation location.

Easy Operation Map, Navigation Guide and Navigation Keys

The navigation keys is an intuitive method to navigate the controller's configuration menus and setting its various menus. Navigation arrows even tell you what button to push next.

Programmable Function Keys

It is easy to assign frequently used functions, such as the operation mode switch, Run/Stop, program pattern selection, Remote/Local, alarm latch release, and PID parameter display. The function of an external switch can also be assigned to the front panel key in conjunction with a ladder sequence program.

It is easy to assign frequently used functions, such as the operation mode switch, Run/Stop, program pattern selection, Remote/Local, alarm latch release, and PID parameter display. The function of an external switch can also be assigned to the front panel key in conjunction with a ladder sequence program.

Scrolling Text

The UTAdvanced is equipped with a scrolling text feature that fully lists the parameter being modified. There is no guessing what parameter you are looking at. It is possible to turn off scrolling the text function.

Multiple Language Support

The UTAdvanced is fluent in multiple languages — English, Spanish, French, and German. The use of the UTAdvanced by local language operators is not an obstacle.

User Settable Default Values

Parameter values (SP, P, I, D, ALM1, etc.) configured by the user can be stored in the controller as the default values. Even if a parameter set value is accidentally changed, it can be restored to the original value with a simple operation.

Parameter values (SP, P, I, D, ALM1, etc.) configured by the user can be stored in the controller as the default values. Even if a parameter set value is accidentally changed, it can be restored to the original value with a simple operation.

Now Available in Two Colors (White or Black)

Now you can choose a color that matches your work area: white (light gray), or black (light charcoal gray).

Parameter Setting

LL50A Parameter Setting Software (sold separately) allows for easily setting parameters.

Message Function

Using the message function and turning the contact input on/off, the message registered beforehand can be displayed on PV display by interrupt.The message is registered using LL50A Parameter Setting Software.The messages are limited to 20 alphanumeric characters. A maximum of four messages can be registered.

Quick Setting Function

Minimum parameters necessary for operation can be set.

Security Function

The password function can prevent inadvertent changes to the parameter settings. If a password is set, the password is required when moving to the Setup Parameter Setting Display. When the password is verified, can be changed to the Setup Parameter Setting Display.

Networking

Communication Functions

A simple and easy network connection is provided!

A built-in function in the controller eliminates the need for a converter and makes wiring simple.

Modbus/TCP

Modbus TCP/IP, a protocol that allows the controller to connect to any Ethernet network and have the ability to exchange data with the computers or devices on that network.

- Allows control devices to be integrated into an application simply.

- Works with any Modbus TCP/IP compliant software.

- Support for Modbus function codes 03, 06, 08 & 16.

- Gateway function allows RS-485 Modbus devices to communicate via Ethernet.

- Reduced labor costs in wiring and setup of a communications network.

- Physical Layer: 10 BASE-T/100 BASE-TX

- Maximum number of connection: 2

Modbus/RTU

The data of UTAdvanced (slave units) can be displayed and saved on the DXAdvanced using the Modbus RTU function.

Open Network (PROFIBUS-DP, CC-Link, DeviceNet)

Embedded open networks will provide direct connection to PLC's.

- Reads data from UTAdvanced

- Writes parameter setting value to UTAdvanced

Example:

Peer to Peer

The use of the ladder sequence program makes it possible to exchange analog data and status data between communication-capable UTAdvanced.

Example: A UTAdvanced in which an input error occurs sends a signal to another UTAdvanced to enable that UTAdvanced switch to MAN operation, thus shifting the whole system into a safe mode. In such a case, the safety mechanism can be built into the UTAdvanced and is not required in the host system.

Coordinated Operation

In coordinated operation, a single UTAdvanced termperature controller is used as a master controller and multiple UTAdvanced or other UTAdvanced digital indicating controllers as slave controllers.

The slave controllers are operated in accordance with the actions of the master controller.

PC-Link

A protocol used for communicating with a general-purpose personal computer, or UTAdvanced series link module and serial communication module of FA-M3R (range-free controller).

Reliability

Dependable 3 year warranty*1

Backed by the high reliability and quality that Yokogawa has cultivated over many years.

RoHS/WEEE compliant

UTAdvanced is environmentally safe when disposing.

Dust-proof and drip-proof front panel (NEMA4*2 /IP66)

UTAdvanced can also be used for food-processing equipment with washable control panels.

- The 3 year warranty extends 36 months after shipment from our factory.

- Hose down test only.

Specifications

| ITEM | UT75A | |

|---|---|---|

| PV input | Input type | Universal input (TC, RTD, mV, V, mA) |

| Number | 1(Std) 2(Max) | |

| Indication accuracy | ±0.1% of F.S. | |

| Number of Control loops | 1(Std) 2(Max) | |

| Control scan period | 50, 100, 200 msec | |

| PV/SP data display | 14-segment, 5 digits, Bar graph LCD display | |

| Control outputs (MV) | Type | Relay, Voltage Pulse, Current |

| Algorithm | ON/OFF, PID (Continuous, Time-proportional), Heating/Cooling, Position-proportional | |

| Digital inputs | Number | 3(Std) 8(Max) |

| Type | SP No.Change, PID No. Change, A/M Change, etc | |

| Digital outputs | Number | 3(Std) 8(Max) |

| Function | PV High, PV Low, Dev High, etc | |

| Number of Program pattern | Number | 1 |

| Number of program segment | Number | 20(Max) |

| Retransmission | Number | 1 |

| Type | PV, SP, OUT, etc | |

| Remote (aux.) input (option) | Number | 1 or 2 |

| Type | 1 to 5 V, etc | |

| Communication (option) | Number | 1 or 2 |

| Type | RS-485, Ethernet, PROFIBUS-DP, CC-Link, DeviceNet | |

| Other specifications | Power supply | 100 to 240 VAC (+10%, -15%) or 24 VAC/DC (+10%, -15%) (option) |

| Power consumption | Max 18 VA | |

| Mass | Max 0.5 kg | |

Comparison Chart (UT75A/UT55A/UT52A/UT35A/UT32A)

|

|

|

|

|

|||

| Model | UT75A | UT55A | UT52A | UT35A | UT32A | ||

|---|---|---|---|---|---|---|---|

| Size | 1/4 DIN | ✓ | ✓ | ✓ | |||

| 1/8 DIN | ✓ | ✓ | |||||

| Depth from the panel surface (mm) | 65 | 65 | 65 | 65 | 65 | ||

| Number of Control loops | Standard (Maximum) | 1(2) | 1 | 1 | 1 | 1 | |

| Control Scan Period | (msec) | Choice 50/100/200 | Choice 50/100/200 | Choice 50/100/200 | 200 | 200 | |

| Display Function | Number of PV Display Digits | 5 | 5 | 5 | 5 | 5 | |

| Active Color PV Display Function | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Guide Scroll Display Function | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Message Display Function | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Bar graph display (Number) | ✓(2) | ✓(2) | ✓(2) | ✓(1) | ✓(1) | ||

| PV Input Indication Accuracy | (% of F.S.) | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | |

| PV Input Type | TC | ✓ | ✓ | ✓ | ✓ | ✓ | |

| RTD (3-wire) | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| RTD (4-wire) | ✓ | ✓ | ✓ | ||||

| mV, V | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| mA | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Number of Analog Inputs | Standard (Maximum) | 1(4) | 1(4) | 1(2) | 1 | 1 | |

| Number of SPs (PIDs) | Maximum | 20(16) | 8 | 8 | 4 | 4 | |

| Number of Control Modes | Maximum | 9 | 8 | 8 | 1 | 1 | |

| Number of Control Types | Maximum | 8 | 8 | 8 | 5 | 5 | |

| Control Output | Type | Relay Contact Output, Voltage pulse output, Current output | ✓ | ✓ | ✓ | ✓ | ✓ |

| Algorithm | ON/OFF | ✓ | ✓ | ✓ | ✓ | ✓ | |

| PID (Continuance, Time Proportion) | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Position proportional | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Heating/cooling | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Number of Analog Outputs | Standard (Maximum) | 2(3) | 2(3) | 2(3) | 2 | 2 | |

| Number of Digital Inputs | Standard (Maximum) | 3(8) | 3(9) | 3(5) | 2(7) | 2(4) | |

| Number of Alarms | 8 | 8 | 8 | 4 | 4 | ||

| Number of Digital Outputs | Standard (Maximum) | 3(8) | 3(18) | 3(5) | 3(8) | 3(5) | |

| Communication | RS-485 communication (Maximum) | ✓(2) | ✓(2) | ✓(1) | ✓(1) | ✓(1) | |

| Ethernet communication | ✓ | ✓ | ✓ | ||||

| Open Network (CC-Link/PROFIBUS-DP/DeviceNet) | ✓ | ✓ | ✓ | ||||

| Various Function | Quick Setting Function | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Split Computation Output Function | ✓ | ✓ | ✓ | ||||

| Ratio and Square Root Extraction Function | ✓ | ✓ | ✓ | ||||

| Remote SP Function | ✓ | ✓ | ✓ | ||||

| 24 V DC Loop Power Supply Function | ✓ | ✓ | ✓ | ✓ | |||

| Heater Break Alarm Function | ✓ (Standard type) |

✓ (Standard type) |

✓ (Standard type or Heating/ cooling type) |

✓ (Standard type or Heating/ cooling type) |

|||

| Ladder Sequence Function | (Number of max. steps) | ✓(1000) | ✓(500) | ✓(500) | ✓(300) | ✓(300) | |

| Other specifications | Power Supply | AC100 V to 240 V | ✓ | ✓ | ✓ | ✓ | ✓ |

| AC/DC 24 V | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Dust and waterproof Level of Front Panel | NEMA4 *1 (IP66) | NEMA4 *1 (IP66) | NEMA4 *1 (IP66) | NEMA4 *1 (IP66) | NEMA4 *1 (IP66) | ||

| Configuration Tool | Via Light-loader Communication | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Via Maintenance Port Communication |

✓ | ✓ | ✓ | ✓ | ✓ | ||

| Via RS-485/Ethernet communication |

✓/✓ | ✓/✓ | ✓/- | ✓/✓ | ✓/- | ||

The table above includes specifications of the standard models only.

* 1: Hose down test only.

Input Range

| Input type | |

|---|---|

| TC | K, J, T, B, S, R, N, E, L, U, W PL-2, PR20-40, W97Re3-W75Re25 |

| RTD | JPt100, Pt100 |

| DC Voltage | 0.4 to 2.0 V, 1.0 to 5.0 V, 0.0 to 2.0 V, 0 to 10 V, -10 to 20 mV, 0 to 100 mV |

| DC Current | 4 to 20 mA, 0 to 20 mA |

Resources

With advances in process automation comes a greater need for level measurement and control. As pressure on at the bottom surface of a liquid is proportional to the height of the liquid's surface, you can measure pressure using a differential pressure transmitter to detect the level of the liquid, acquire the data on the UT75A Digital Indicating Controller, and use the measurements to control the tank level.

Adding the CP calculation option to the advanced UT75A Digital Indicating Controller enables CP (Carbon Potential) control. CP calculation can be carried out with just one line of a UT75A ladder program.

Downloads

Brochures

Instruction Manuals

General Specifications

Technical Information

Drawings

Looking for more information on our people, technology and solutions?

Contact Us

Protecting Knowledge of Users

Protecting Knowledge of Users PID control

PID control