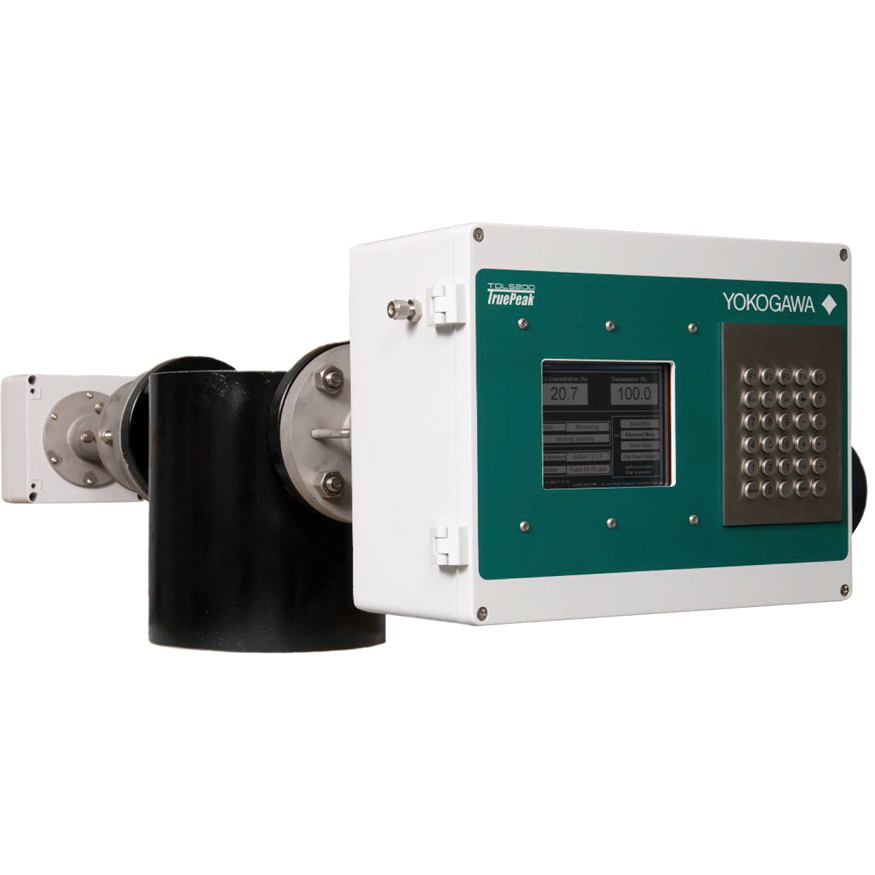

The new Yokogawa TruePeak Tunable Diode Laser Spectroscopy (TDLS200) Analyzer is one of the most robust process analyzers available designed to make fast, accurate measurements on near-infrared absorbing gases in harsh process environments, where conditions are of high temperature or pressure, it can be used under difficult conditions including environments involving corrosive, aggressive and high particulate content materials.

The TruePeak Tunable Diode Laser Spectroscopy (TDLS200) Analyzer is ideally suited to in-situ analysis, particularly for measurements in environments involving changing pressure or temperature. It can operate with process pressures up to 20 bar absolute and process temperature up to 1500°C, has a fast response (from 2 to 20 seconds), and is interference-free for most applications.

It can measure Carbon monoxide (CO), from low ppm detection limits to percentage levels at process temperatures of up to 1500°C. The analyzer can also be used for measuring parts per million moisture content in corrosive and aggressive process streams including chlorine and hydrocarbons.

It offers a range of flexible installation options, and features on-board diagnostics. Using a tunable diode laser as a monochromatic light source offers the benefits of sensitivity, selectivity to resolve single absorption lines, and power – to overcome the effects of optically thick environments with high particulate loading.

The new instrument is one of the most robust process analyzers available. In addition to operating in conditions of high temperature or pressure, it can be used under difficult conditions including environments involving corrosive, aggressive and high particulate content materials.

The TruePeak Tunable Diode Laser Spectroscopy (TDLS200) Analyzer is a compact stand-alone unit with available in a 4´20 vacuum fluorescent display for scrolling information or a 7-inch color screen with keypad. The instrument offers a range of interfaces including Ethernet, USB communication for safe or hazardous areas.

The instrument includes three configurable 4-20 mA outputs, two 4-20 mA inputs in case of temperature and pressure compensation, and relay outputs including warning/fault relays and 3 valve drivers for validation or stream switching.

The ability of the new The TruePeak Tunable Diode Laser Spectroscopy (TDLS200) Analyzer to carry out accurate online process measurements makes it ideally suited to applications such as combustion control, where it can be used to optimize the combustion process by measuring excess oxygen and carbon monoxide on a precise and continuous basis.

It also allows carbon monoxide to be accurately measured on a continuous basis at low ppm levels so that air fuel ratios can be precisely and continually optimized.

Other potential applications of the TruePeak Tunable Diode Laser Spectroscopy (TDLS200) Analyzer include the monitoring of carbon monoxide, methane and moisture to enable burner flame-out and process tube leaks to be identified; the measurement of oxygen on flare lines, alkylation units and gas plants; the monitoring of carbon monoxide and oxygen on fluid catalytic cracking units for safety and catalyst regeneration; or the detection of low ppm concentrations of moisture in hydrocarbons in catalytic reforming processes.

Details

- In Situ Analysis

- Fast Response (2-20 seconds)

- Interference Free for most applications

- TruePeak measurement capable of measuring under changing pressure, temperature and background

- Process Pressures up to 20 Bar

- Process Temperature up to 1500°C

- Optical Measurement, no sensor contact with process

- Low LTCO (no moving parts, high MTBF for components)

- Flexible Installation Options

- On Board Diagnostics

- ATEX Group II for zone 1 (Cat 2G) or 2 (Cat 3G) with purge systems

Resources

Cracking is used to break down the long chains of hydrocarbons that crude oil is comprised of into smaller hydrocarbon chains. Cracking was originally done thermally, and continued until 1933, when the Houdry process for catalytic cracking was developed. The Houdry units were preferentially adopted in following years due to producing a much higher portion of higher octane gasoline during cracking. The process was improved once again and became known as Thermofor Catalytic Cracking (TCC) and involved the use of a moving catalyst bed. The first commercial TCC unit was developed in 1943 in Beaumont, Texas and it is speculated that TCC and Houdry units played a large part in the allied victory of World War II. Around the same time, MIT professors Lewis and Gilliland developed a Fluidized Catalytic Cracking Unit (FCCU) which involves passing just enough air though the catalyst that it floats, allowing it to function as a fluid. FCCUs have since become the dominantly produced cracking unit. FCCUs used in conjunction with catalyst zeolite Type Y have increased the yield (~45% of total yield from the feed) and octane rating of gasoline far above of what would be achievable with thermal cracking. As of 2011, catalytic cracking produced over 8,700,000 barrels of motor gasoline per day in the US alone.

An accurate measurement of the carbon monoxide (CO) concentration in the boiler flue gas can be used to achieve the goals of combustion efficiency, pollutant emissions reduction, and safe operation. By measuring the concentration of CO, power plants are able fine tune the air to fuel ratio used on the burners to obtain the highest combustion efficiency.

Electrolysis plants create hydrogen and chlorine from a brine solution. Chlorine gas generated from the anolyte of the electrolysis tank generally contains between 0.5 to 2.0 vol% H2O. The sample is then cooled and filtered to remove brine, subsequently coming out as wet chlorine gas. The wet gas is sent to a drying tower where it is treated with sulfuric acid to get moisture down to the ppm level.

In this eBook we explain how to improve fired heaters safety & efficiency by controlling combustion using TDLS technology. Download it now and learn:

- The 4 top industry challenges related to fired heaters

- How to efficiently and safely manage combustion

- How TDLS technology can improve operational excellence in fired heaters

In recent years, shale gas extraction technology has made rapid progress, inducing a shale gas revolution mainly in the USA. Thus, the need for analysis of hydrocarbon gases, including natural gas, is expected to grow rapidly. Traditionally gas chromatography has been used for the analysis of hydrocarbon gases; it can accurately measure the concentration of each hydrocarbon component in a sample of natural gas.

Combustion furnaces such as heating furnaces and boilers in plants include various sizes and types, and serve as energy sources, that is, they are cores in all production activities. Because a large amount of fuel such as gas or fuel oil is consumed in plants, their combustion efficiency directly affects the performance and running cost of the plants.

A laser gas analyzer employing the tunable diode laser absorption spectroscopy (TDLAS) method has a feature capable of measuring the concentration of the sample gas with high selectivity for gas components and without contact only by irradiating the gas sample with light from a tunable diode laser. Thus fast and accurate in-situ measurements can be performed in process lines under various measurement conditions.

Tunable diode laser analyzers optimize combustion through direct measurement of O2, CO and methane.

Downloads

Brochures

Instruction Manuals

- Addendum Instruction Manual for TDLS200 - Furnaces, Heaters & Large Scale Combustion (4.3 MB)

- TDLS200 Tunable Diode Laser Spectroscopy Analyzer (7.5 MB)

- Addendum Instruction Manual for TDLS200 / Furnaces, Heaters & Large Scale Combustion (4.3 MB)

- TDLS200 Tunable Diode Laser Spectroscopy Analyzer Start-up Manual (1.2 MB)

General Specifications

Certificates

- ATEX/CE (780 KB)

- Exida FMEDA SIL Report (257 KB)

- Supplemental ATEX Certification (1.3 MB)

- TDLS200SJ - TIIS- Japanese Certification (40 KB)

- TDLS200SJ-B - TIIS- Japanese Certification (41 KB)

Forms

Videos

Fired heaters are the largest energy consumer in the manufacturing sector and represent a tremendous opportunity for energy savings. However, energy efficiency is not the only concern for fired heaters. Compliance and safety are continuous challenges.

In this one-hour presentation, we will discuss:

- How to improve fired heater safety and efficiency by controlling combustion using Tunable Diode Laser Spectrometers (TDLS) technology

- The 4 top industry challenges related to fired heaters

- How to efficiently and safely manage combustion

- How TDLS technology can improve operational excellence in fired heaters

Looking for more information on our people, technology and solutions?

Contact Us