Introduction

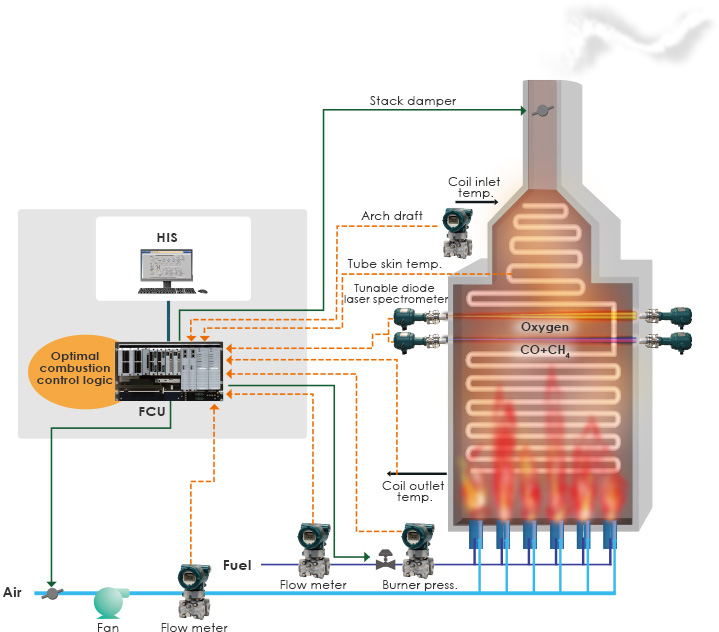

Fired heaters are used for various processes in oil refining and petrochemical plants. It is widely known that precision control of O2 and CO concentrations in combustion gas is a factor in reducing environmental impacts and increasing manufacturing efficiency. Still, it is difficult to use by-product gas in fuel (its calorific value is not consistent), and there has been no general-purpose technology for real-time measurement of combustion states that are not uniform across the furnace. Therefore efforts to equip fired heaters with optimal combustion control has not advanced for many years, and often engineers are forced to run fired heaters in a manner that sacrifices efficiency for safety. Yokogawa's optimal furnace combustion control solution offers a comprehensive way to meet these furnace related challenges. With the TDLS Analyzer at the core, the ability to use a laser that crosses large fired heaters to directly measure the average concentration of combustion gas in real time is a game changer. To this we add optimal combustion control logic that enhances safety, and a site measurement solution that brings more stable control. This enables operation that always maintains optimal combustion gas concentration even in fired heaters with non-uniform temperature profiles.

What is the Core Product, the TDLS Analyzer?

Offers direct, fast analysis inside 30 m diameter, 1000°C fired heaters

The TDLS series irradiates gases with a laser to measure concentrations of various gases that have absorption in the near-infrared region, including but not limited to O2, CO, CH4, NH3, and H2O. The sensor is partitioned by a glass window, ensuring no contact with the measured gas. Therefore, even for high-temperature gases such as those inside burners in larger fired heaters, you can stably measure average values up to 1500°C and 30 m. Since no sampling is necessary, you can get real time measurements in less than five seconds. And since there are no consumable parts, once you install it there are almost no running costs.

Customer Benefits

- Reduces Fuel Consumption and Emissions (CO2 and NOx) through Increased Combustion Efficiency

- Conforms to API-556 to Maintain Safety

- Correct Heat Balance Increases Availability

Yokogawa's One-Stop Solution

Fired Heater Experts Directly Survey Sites

To identify our customers' precise needs in measuring, control, and furnace processes, our highly knowledgeable and experienced consultants will visit your plants. With the provided furnace drawing in hand, they will survey the operating conditions in the control room, the equipment on the site, and other factors.

Propose Combustion Optimization Strategy and Show Benefits Quantitatively

Based on the result of the survey, they will plan a control strategy and additions or improvements to existing measuring equipment. At the same time, they will provide concrete numerical estimates of expected results.

Propose an Instrumentation Plan Based on Existing Equipment

Starting with new TDLS, they will create a proposal for the instruments' measuring locations, installation methods, target quantities, and other recommendations that are customized to your fired heaters.

The New Standard Supports Operation of Any Type of Furnace

The Yokogawa Electric fired heater optimization solution has introduced equipment into oil refineries including distillation, catalytic reforming, aromatic units, and hydro-desulfurization. The result has been more stable furnace operation and increased combustion efficiency, and in many cases we achieved a 5 % reduction in fuel. The Yokogawa Electric fired heater optimization solution sets a new standard that can simultaneously solve environmental and manufacturing efficiency issues.

Related References

Mr. László Cserna, Senior Project Manager of MOL Group who is headquartered in Hungary and one of the major players in the European Industrial sector, shares his experience and perspective on MOL's effort in reducing their energy and carbon footprint.

Industries

-

Chemical

Chemical plants rely on continuous and batch production processes, each posing different requirements for a control system. A continuous process calls for a robust and stable control system that will not fail and cause the shutdown of a production line, whereas the emphasis with a batch process is on having a control system that allows great flexibility in making adjustments to formulas, procedures, and the like. Both kinds of systems need to be managed in available quality history of product, and to be able to execute non-routine operations. With its extensive product portfolio, experienced systems engineers, and global sales and service network, Yokogawa has a solution for every plant process.

-

Oil & Gas Downstream

The oil & gas downstream industry has been facing an increasing number of challenges in recent years. These include the changing characteristics of the feedstock to be processed, aging of process facilities and equipment, rising cost of energy, lack of skilled plant operators who can run a refinery safely and efficiently, and the ever-changing requirements from both the market and the customer.

Over the years, Yokogawa has partnered with many downstream companies to provide industrial solutions focused on solving these challenges and problems. Yokogawa's VigilantPlant solutions have helped plant owners to achieve maximum profitability and sustainable safety within their plants.

-

Petrochemical

Petrochemical companies’ needs are extremely diverse. To come out ahead in today’s highly competitive marketplace, producers are striving to improve quality and productivity. Yokogawa provides tailor-made solutions for these needs based on its long and wide-ranging experience in this field.

-

Refining

In the ever changing marketplace, refineries are seen not only as crude processing units but also as profit centers. At the same time, there is a keen awareness of the need for safety at such facilities. A total production solution that encompasses planning, scheduling, management, and control is required to achieve long-term goals for profitability, efficiency, and environmental protection. With years of expertise in the automation field, Yokogawa can bring you affordable total solutions for improved operability and a cleaner world.

Related Products & Solutions

-

Combustion Safety & Optimization

Yokogawa is proud to offer a single source solution to improve combustion safety and efficiency in fired heaters.

-

In-Situ Gas Analyzer TDLS8000

Yokogawa’s new TDLS™8000 houses all of the industry’s leading features in one robust device. The platform design is for in situ measurements which negate the need for sample extraction and conditioning.

-

Distributed Control System (DCS)

Our distributed control system (DCS) enables automation and control of industrial processes and enhanced business performance. Over 30,000 systems entrust Yokogawa DCS to deliver their production goals.